As a versatile, multiphysics CFD software, FLOW-3D has all the necessary features to model the wide range of physical processes found in today’s most complex product designs. FLOW-3D has been known since its inception 40+ years ago as the most accurate CFD tool on the market for modeling free surface fluid applications, and it continues to evolve and improve with the addition of more physical models, optimization, and post-processing capabilities. Our extensive modeling capabilities allow our users to successfully solve the toughest CFD problems and optimize designs and processes in research, development and production.

Multiphysics Playlist

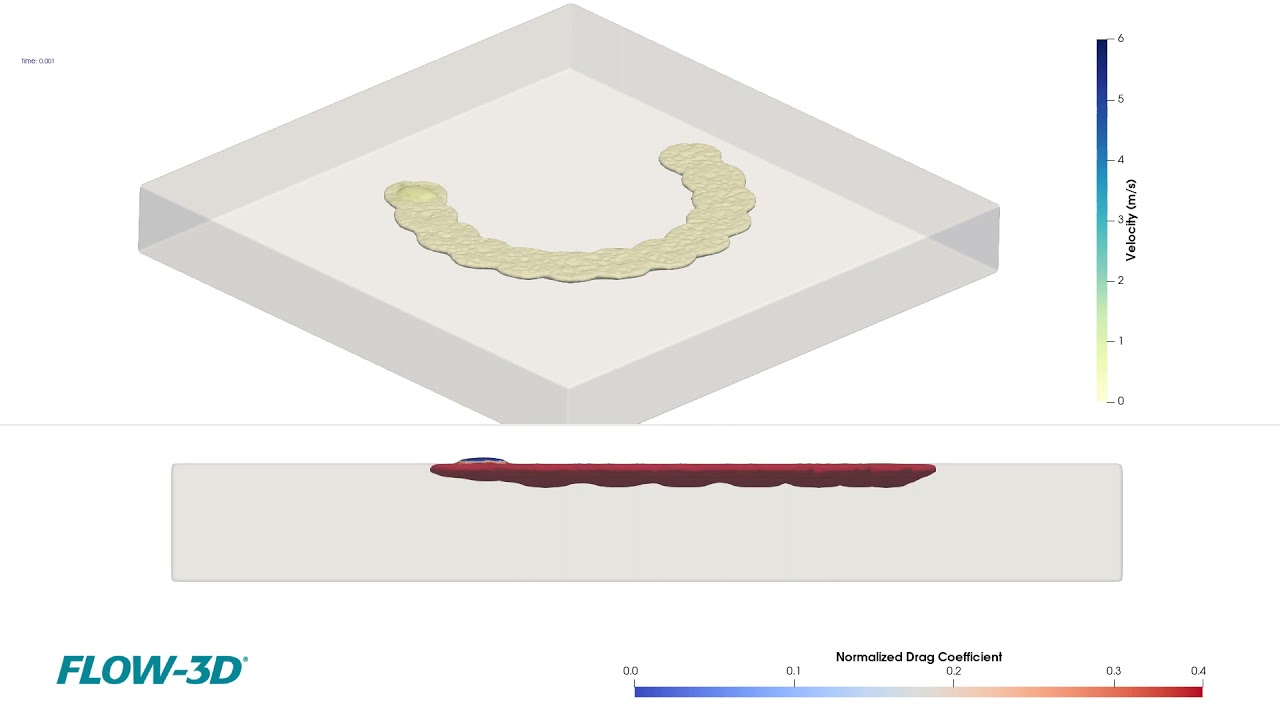

The new droplet/bubble source model allows either spherical droplets or bubbles to be emitted at defined intervals from a point source. This source can be either stationary or its motion can be defined in a tabular fashion. The initial velocity of the droplet or bubble can also be defined in three dimensions. All physical models are compatible with this model so that typical applications such as porous media flow, evaporation/solidification, and surface tension can be simulated. In this example, a droplet source moves in a circular pattern while ejecting droplets downward at a velocity of 10 m/s into a porous medium to create a ring-shaped design.

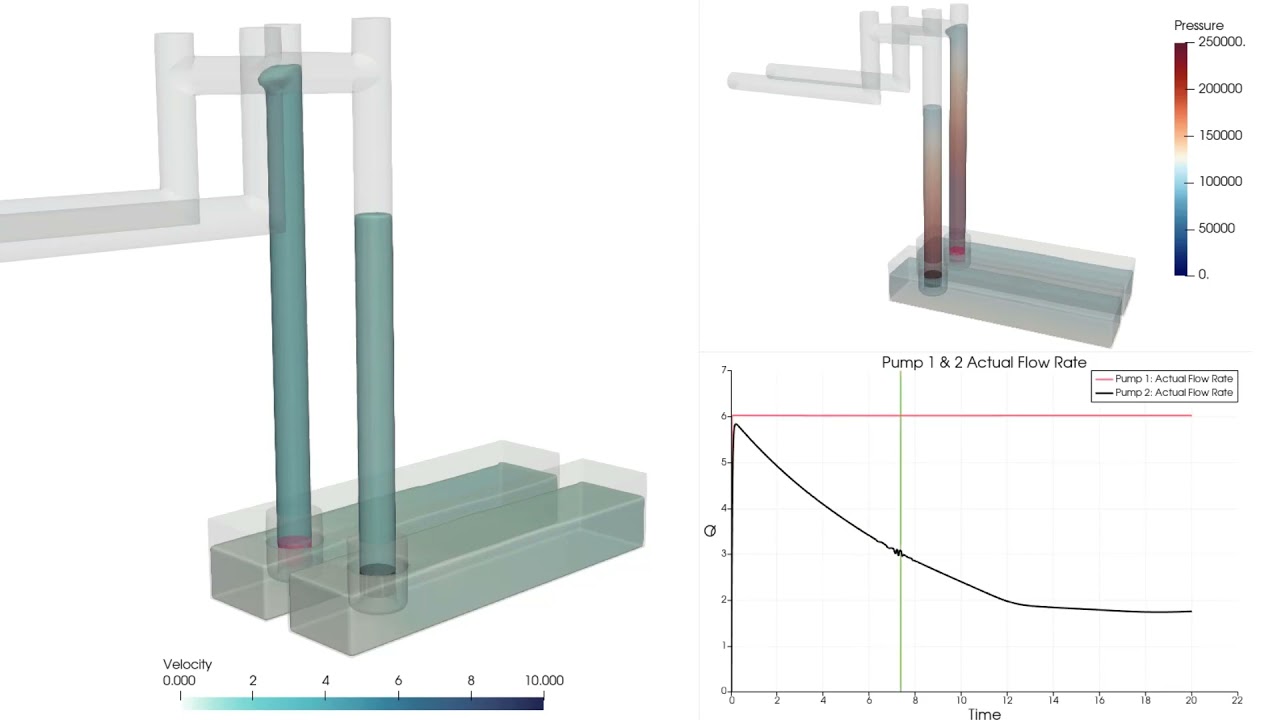

FLOW-3D’s new axial pump model allows users to mimic the net effect of an axial pump in their simulations. There are two options with respect to the pump behavior. The first option is to prescribe either a volumetric flow rate or a flow velocity through the pump so that the fluid is moved at the specified rate. This option is appropriate when an operating flow rate is provided for the pump. The second option provides a more complete definition of the pump operation based on a pump performance curve.

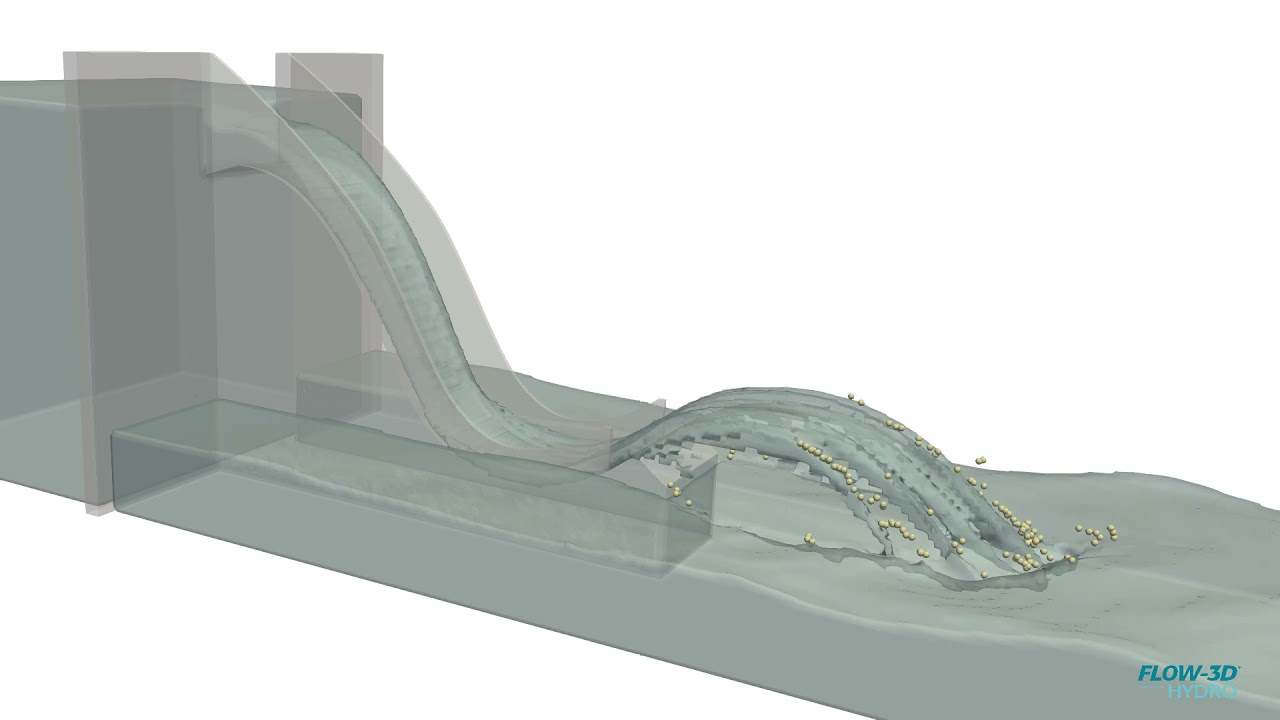

The accuracy and robustness of the sharp-interface tracking VOF methods in FLOW-3D have been enhanced by combining them with fluid particles. The new particle species, called VOF particles, are used in place of the VOF function to track small fluid ligaments and droplets in the computational domain, achieving better conservation of fluid volume and momentum.

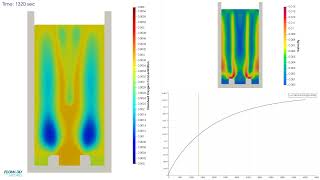

In this simulation, oxygen bubbles are injected from two diffusers at the bottom of the container and allowed to rise in water. As the bubbles rise, oxygen dissolves into water. The image on the left shows the concentration of dissolved oxygen in water. The image on the right shows the water velocity which is induced by the rising oxygen bubbles.

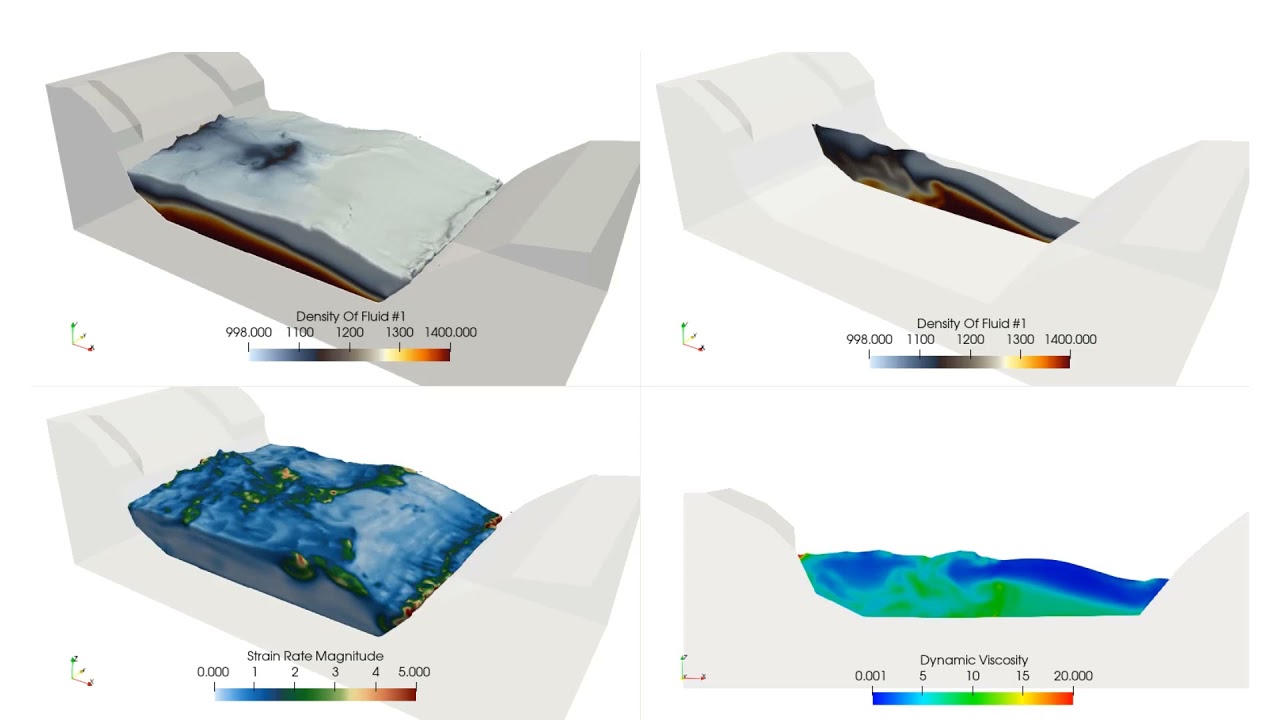

Viscosity is defined as a function of both solid content (density) and strain rate. In this example a dense fluid region slides down into a quiescent pool which at time zero is layered with a dense settled fluid region and clear water above.

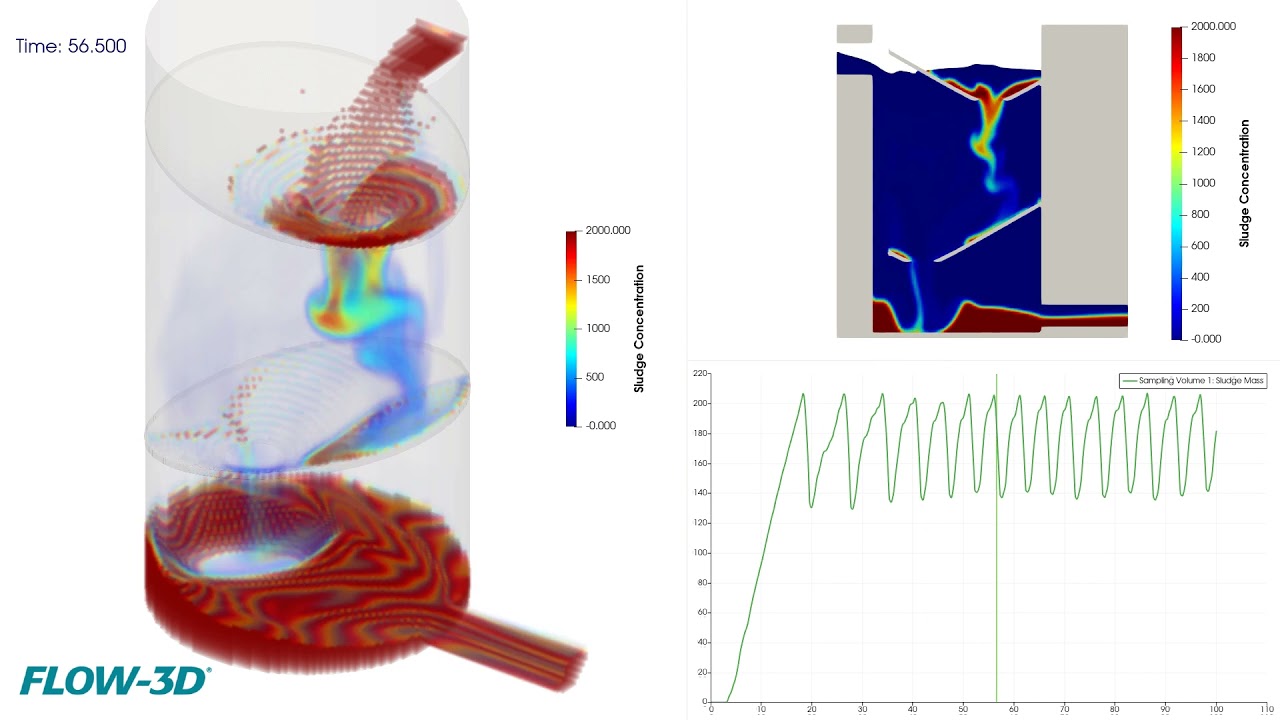

This example represents a sludge decanter that models a mixture of water and sludge entering a decanter and separating. Water is allowed to flow in and out at the back side of the decanter to maintain a relatively fixed level in the decanter. A sampling volume in the bottom of the decanter is used to measure the amount of sludge captured at the bottom. When the sludge mass in the sampling volume reaches 200 kg, a valve opens to release the sludge. The valve closes when the sludge mass drops below 180 kg.

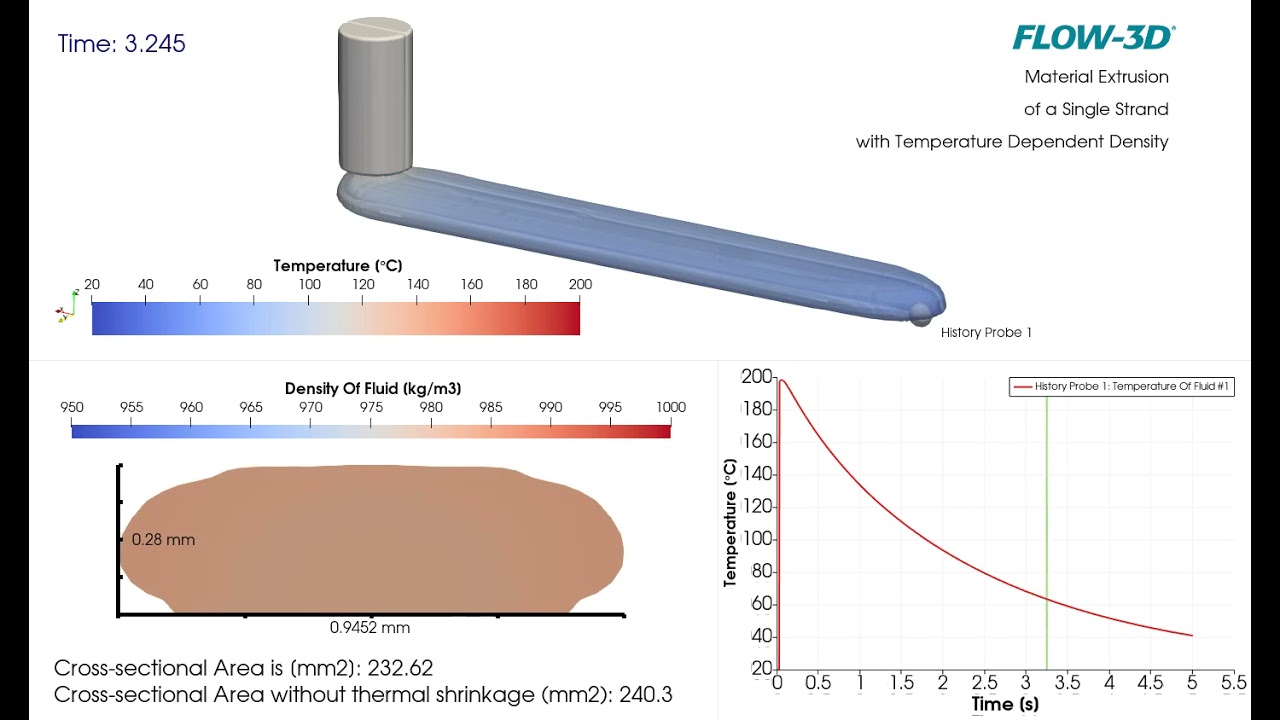

This example demonstrates FLOW-3D‘s capabilities for simulating a material extrusion AM process. In this simulation, a single strand of highly viscous material is extruded and deposited on a stationary substrate. The heat transfer model is activated, and the density is evaluated as a function of strand temperature after the deposition, which allows the material shrinkage to be predicted. The example is post-processed with FLOW-3D POST.

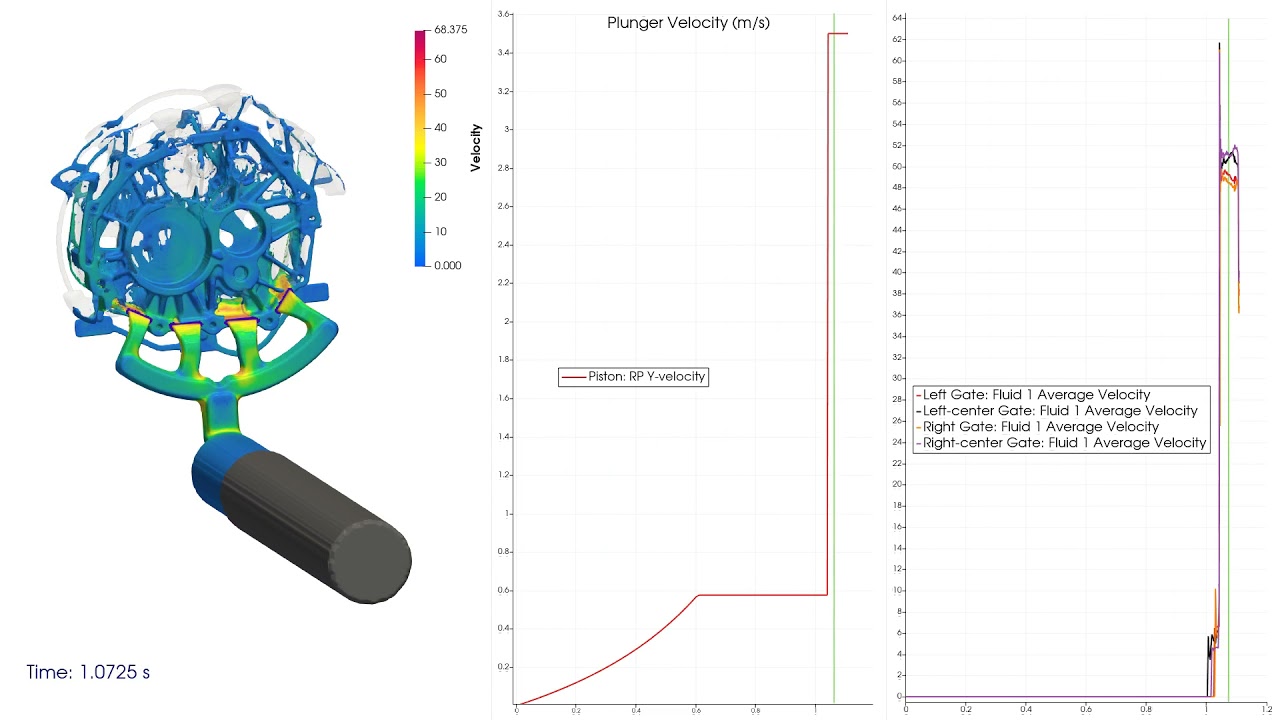

This video demonstrates Active Simulation Control being used to increase data output frequency when fast shot begins so that flow details can be captured. Flux surfaces are placed at the gates to measure the average velocity. When the average velocity exceeds 35 m/s, Active Simulation Control sets the output frequency to 0.0007 seconds for the duration of the simulation.

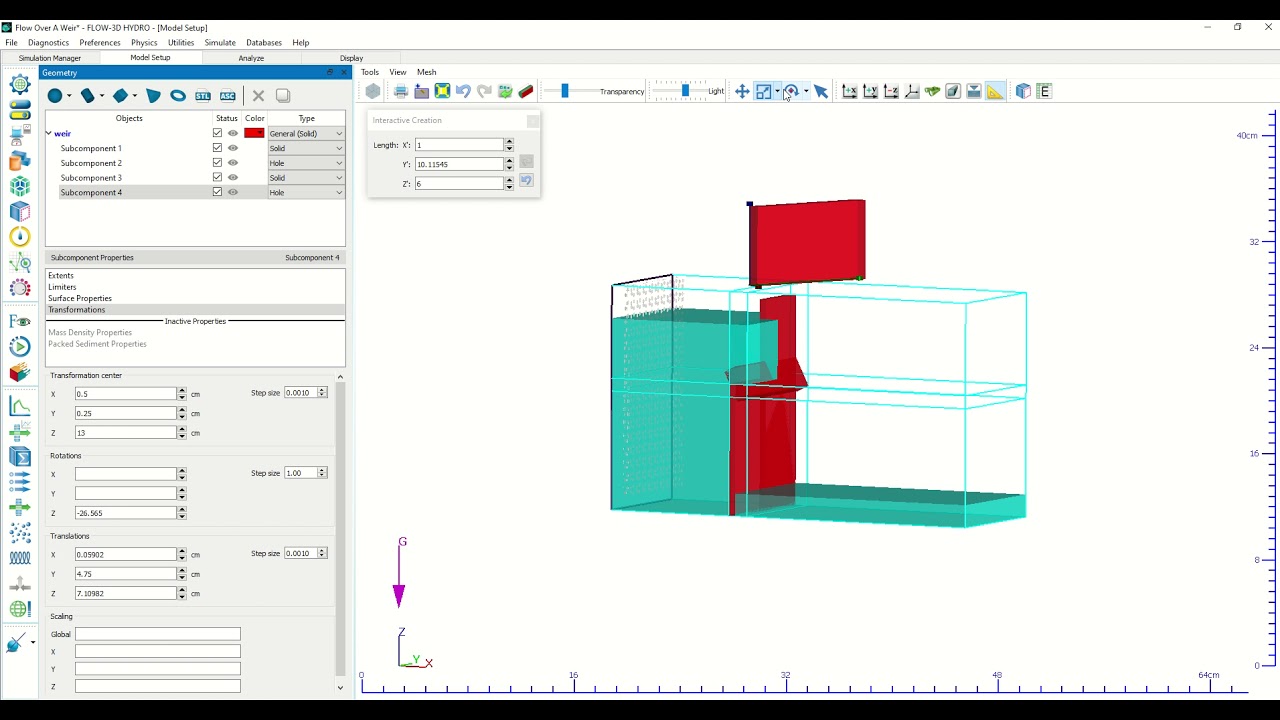

FLOW-3D‘s interactive geometry creation and editing is better than ever, and now includes new interactive tool selection including rotate, move and resize; enter rotate, move, or resize mode by clicking the action and selecting the geometry to modify; and clicking the up arrow icon or hitting the ESC key will return the user to a normal select mode.

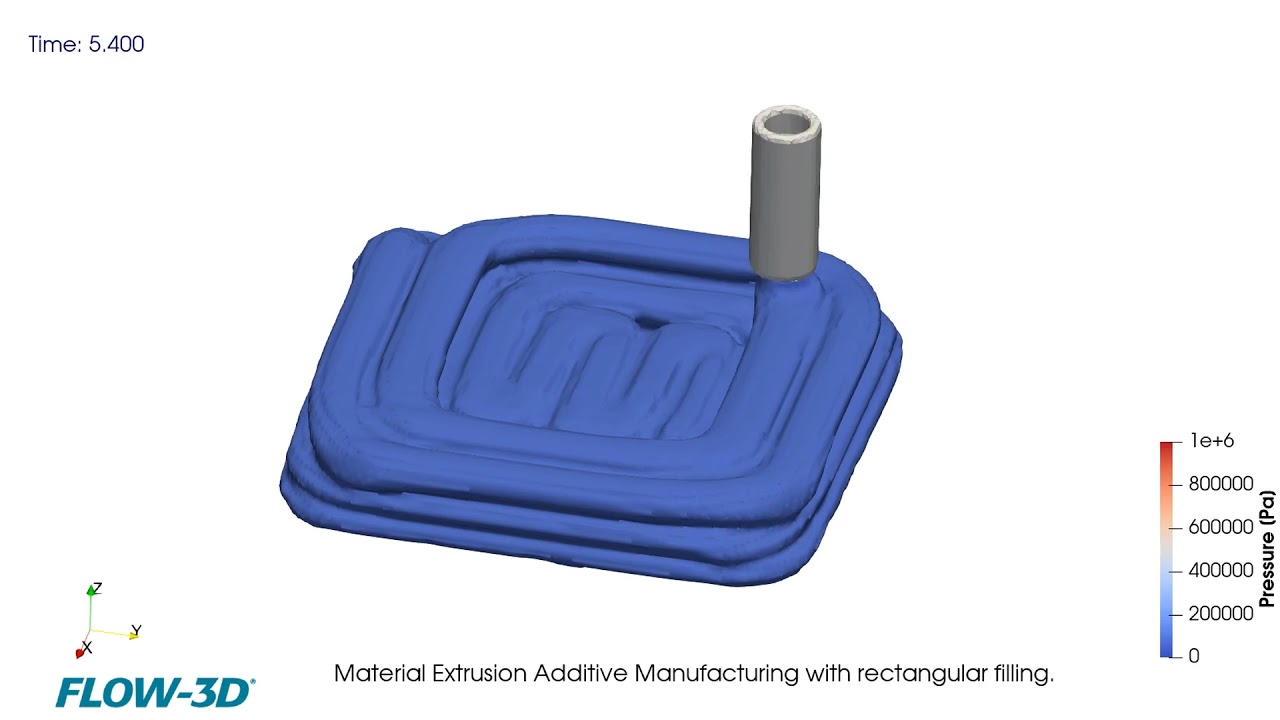

This example demonstrates FLOW-3D‘s capabilities to simulate a material extrusion AM process. In this simulation, the material is approximated as a highly viscous fluid with constant material properties. Four layers with rectangular filling are printed and the deformations of already deposited material under the newly extruded strands can be observed. The example is post-processed with FLOW-3D POST.

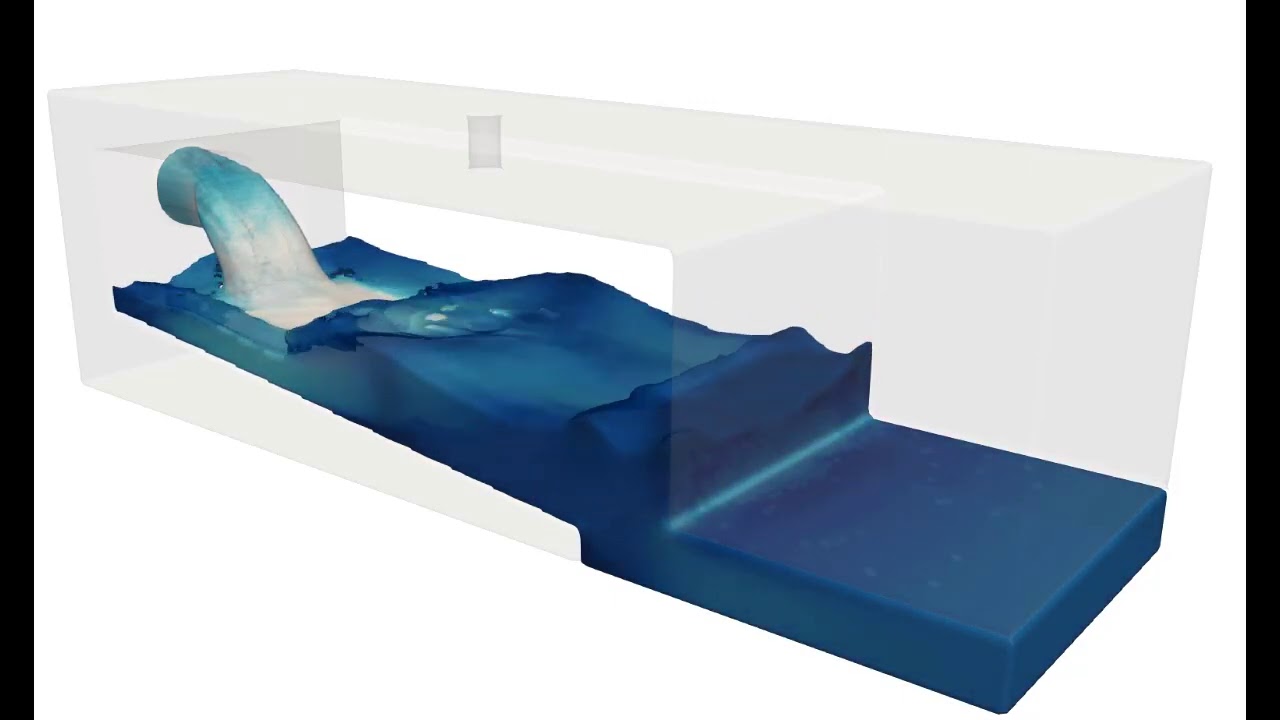

This pre-packaged FLOW-3D HYDRO example of a discharge into a tank uses the Free surface – 2 fluid VOF template available in FLOW-3D HYDRO for users to quickly setup two phase air/water models. Air and water properties, and all the appropriate models and numerical settings are pre-loaded into the simulation, providing a great starting point to model two phase flows, from setup through to post-processing analysis. Learn more about FLOW-3D HYDRO‘s complete CFD solution for the civil and environmental engineering industry at https://www.flow3d.com/products/flow-3d-hydro/water-treatment/

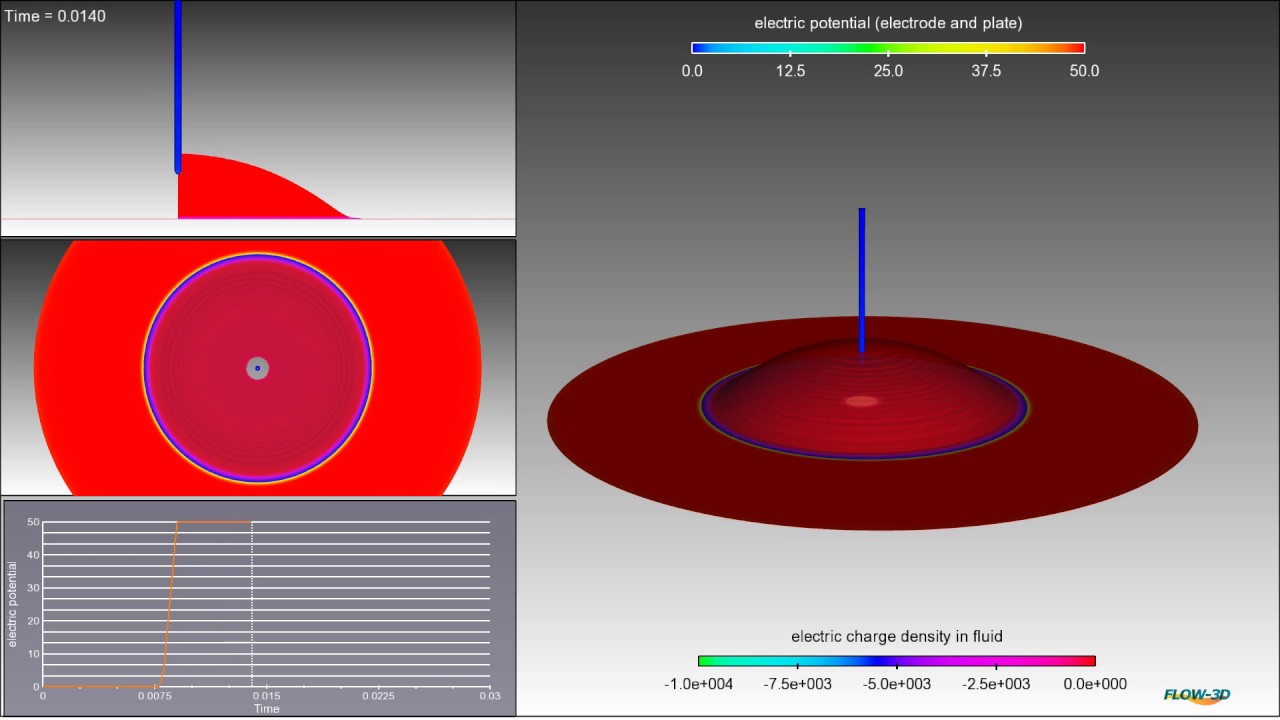

Electrowetting is a technique used to change the apparent contact angle of a dielectric fluid under the influence of electric potential. In this example, the fluid is originally hydrophobic and beads on the surface. However, when a 50V potential difference is applied, the fluid is forced to wet the surface becoming hydrophilic.

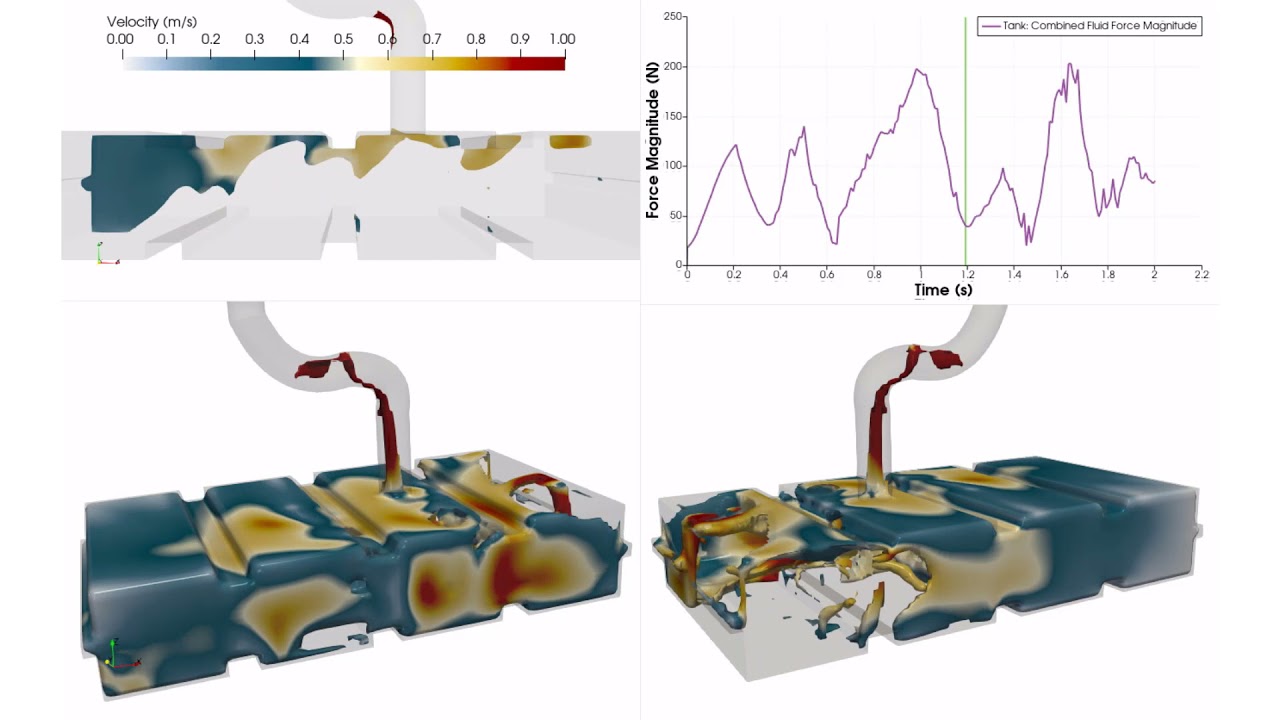

Automotive fuel tanks hold significant fuel mass and are subject to constant vehicle accelerations and decelerations. This presents a structural issue for tank material due to the impact forces. Additionally, sloshing of fuel can cause incorrect reading or damage to measurement devices. Shown here is a simulation in FLOW-3D of fuel sloshing under acceleration plotting velocity contours. The graph shows transient force magnitude on fuel tank. Learn more at https://www.flow3d.com/industries/automotive/

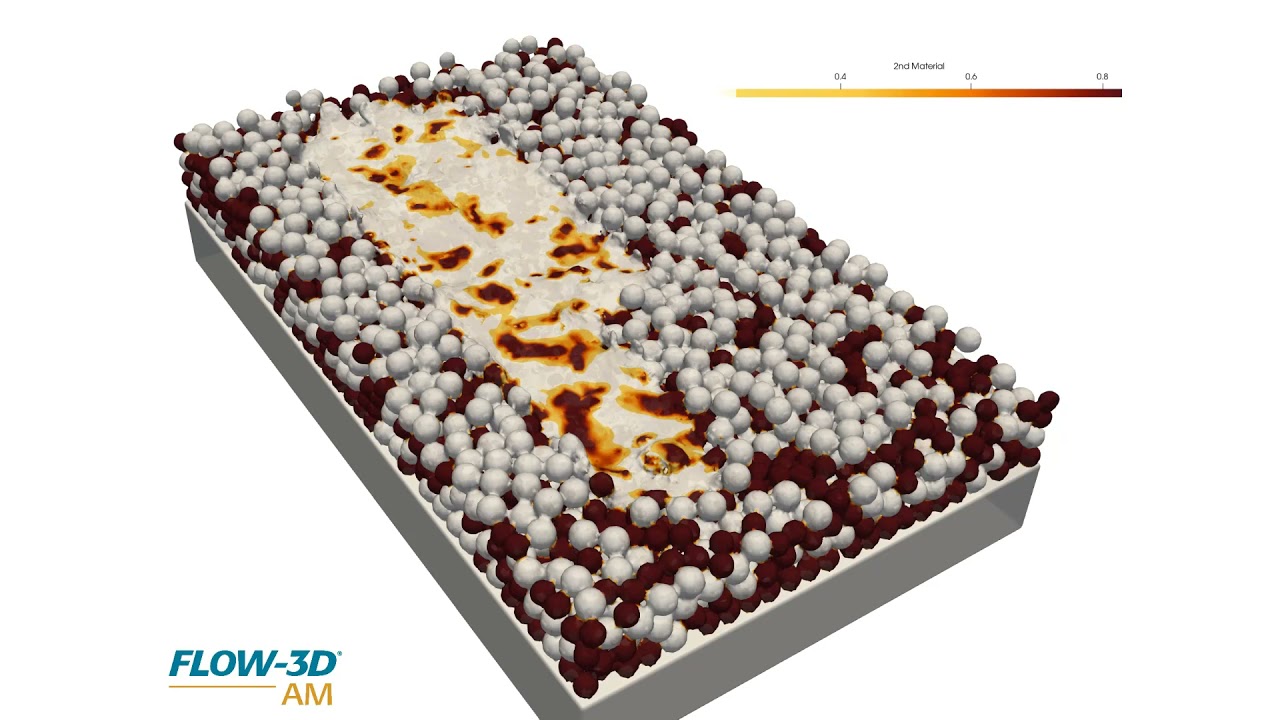

Micro and meso scale simulations using FLOW-3D AM help us understand the mixing of different materials in the melt pool and the formation of potential defects such as lack of fusion and porosity. In this simulation, the stainless steel and aluminum powders have independently-defined temperature dependent material properties that FLOW-3D AM tracks to accurately capture the melt pool dynamics. Learn more about FLOW-3D AM‘s mutiphysics simulation capabilities at https://www.flow3d.com/products/flow3d-am/

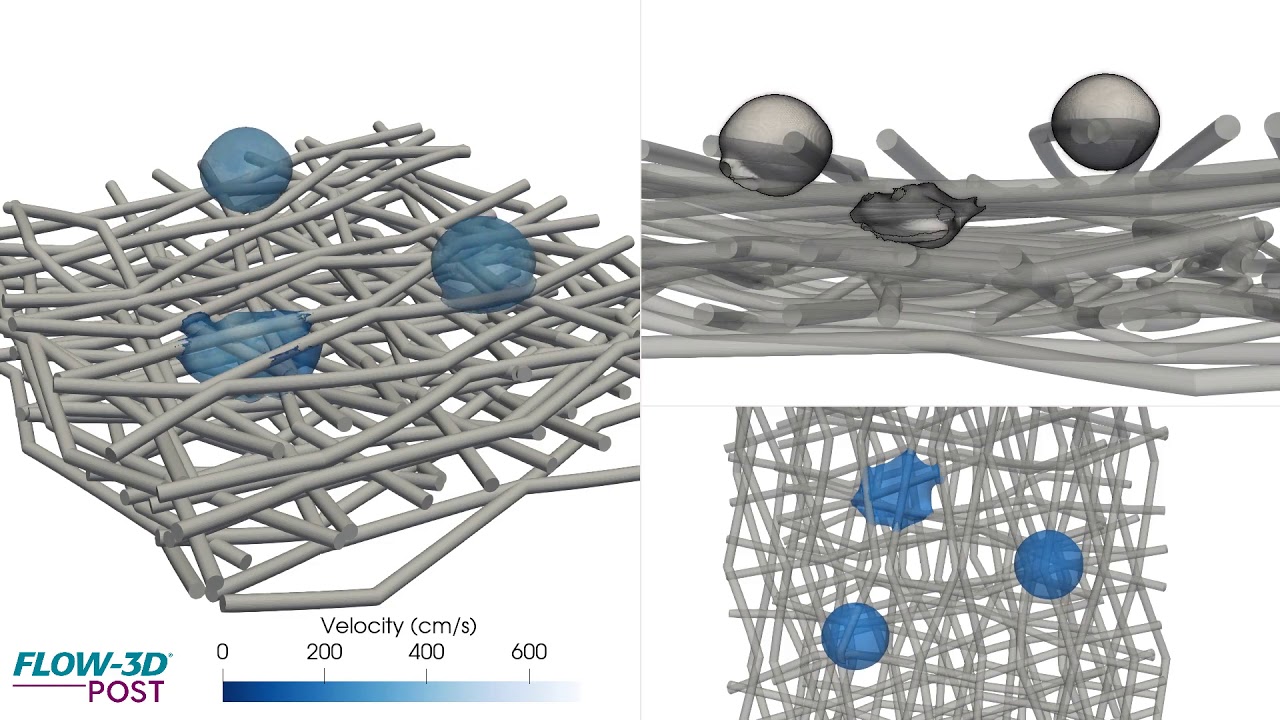

Here, FLOW-3D is used to simulate drop impingement on a fibrous bed, looking at the propagation of the fluid front as it relates to surface tension, contact angle, and viscosity. For more information on this and other coating simulation capabilities, visit https://www.flow3d.com/industries/coating/

Advanced Modeling Capabilities

- One incompressible fluid – confined or with free surfaces

- Two incompressible fluids – miscible or with sharp interfaces

- Compressible fluid – subsonic, transonic, supersonic

- Stratified fluid

- Acoustic phenomena

- Mass particles with variable density or diameter

- Structured finite difference/control volume meshes for fluid and thermal solutions

- Finite element meshes in Cartesian and cylindrical coordinates for structural analysis

- Multi-Block gridding with nested, linked, partially overlapping and conforming mesh blocks

- Conforming meshes extended to arbitrary shapes

- Fractional areas/volumes (FAVOR™) for efficient & accurate geometry definition

- Closing gaps in geometry

- Mesh quality checking

- Basic Solids Modeler

- Import CAD data

- Import/export finite element meshes via Exodus-II file format

- Grid & geometry independence

- Cartesian or cylindrical coordinates

- Fluid structure interaction

- Thermally-induced stresses

- Plastic deformation of solids

- Granular flow

- Moisture drying

- Solid solute dissolution

- Sediment transport and scour

- Sludge settling

- Cavitation (potential, passive tracking, active tracking)

- Phase change (liquid-vapor, liquid-solid)

- Surface tension

- Thermocapillary effects

- Wall adhesion

- Wall roughness

- Vapor & gas bubbles

- Solidification & melting

- Mass/momentum/energy sources

- Shear, density & temperature-dependent viscosity

- Thixotropic viscosity

- Visco-elastic-plastic fluids

- Elastic membranes & walls

- Evaporation residue

- Electro-mechanical effects

- Dielectric phenomena

- Electro-osmosis

- Electrostatic particles

- Joule heating

- Air entrainment

- Molecular & turbulent diffusion

- Temperature-dependent material properties

- Spray cooling

- General Moving Object model with 6 DOF–prescribed and fully-coupled motion

- Rotating/spinning objects

- Collision model

- Tethered moving objects (springs, ropes, breaking mooring lines)

- Flexing membranes and walls

- Porosity

- Finite element based elastic-plastic deformation

- Finite element based thermal stress evolution due to thermal changes in a solidifying fluid

- Combusting solid components

- RNG model

- Two-equation k-epsilon model

- Two-equation k-omega model

- Large eddy simulation

- Internal, external & free-surface flows

- 3D, 2D & 1D problems

- Transient flows

- Inviscid, viscous laminar & turbulent flows

- Hybrid shallow water/3D flows

- Non-inertial reference frame motion

- Multiple scalar species

- Two-phase flows

- Heat transfer with phase change

- Saturated & unsaturated porous media

- General topography

- Raster data interface

- Subcomponent-specific surface roughness

- Wind shear

- Ground roughness effects

- Manning’s roughness

- Laminar & turbulent flow

- Sediment transport and scour

- Surface tension

- Heat transfer

- Wetting & drying

- General boundary conditions

- Symmetry

- Rigid and flexible walls

- Continuative

- Periodic

- Specified pressure

- Specified velocity

- Outflow

- Outflow pressure

- Outflow boundaries with wave absorbing layers

- Grid overlay

- Hydrostatic pressure

- Volume flow rate

- Non-linear periodic and solitary surface waves

- Rating curve and natural hydraulics

- Wave absorbing layer

- Restart from previous simulation

- Continuation of a simulation

- Overlay boundary conditions

- Change mesh and modeling options

- Change model parameters

- Stiff equation solver for chemical rate equations

- Stationary or advected species

- Saturated and unsaturated flow

- Variable porosity

- Directional porosity

- General flow losses (linear & quadratic)

- Capillary pressure

- Heat transfer in porous media

- Van Genunchten model for unsaturated flow

- Massless marker particles

- Multi-species material particles of variable size and mass

- Solid, fluid, gas particles

- Void particles tracking collapsed void regions

- Non-linear fluid-dynamic drag

- Added mass effects

- Monte-Carlo diffusion

- Particle-fluid momentum coupling

- Coefficient of restitution or sticky particles

- Point or volumetric particle sources

- Initial particle blocks

- Heat transfer with fluid

- Evaporation and condensation

- Solidification and melting

- Coulomb and dielectric forces

- Probe particles

- Liquid/liquid & gas/liquid interfaces

- Variable density mixtures

- Compressible fluid with a dispersed incompressible component

- Drift flux with dynamic droplet size

- Two-component, vapor/non-condensable gases

- Phase transformations for gas-liquid & liquid-solid

- Adiabatic bubbles

- Bubbles with phase change

- Continuum fluid with discrete particles

- Scalar transport

- Homogeneous bubbles

- Super-cooling

- Two-field temperature

- Geometry input from Stereolithography (STL) files – binary or ASCII

- Direct interfaces with ParaView, FieldView® & Tecplot® visualization software

- Finite element solution import/export via Exodus-II file format

- PLOT3D output

- Neutral file output

- Extensive customization possibilities

- Solid Properties Materials Database

- Natural convection

- Forced convection

- Conduction in fluid & solid

- Fluid-solid heat transfer

- Distributed energy sources/sinks in fluids and solids

- Radiation

- Viscous heating

- Orthotropic thermal conductivity

- Thermally-induced stresses

- State-of-the-art post-processing tool, FlowSight™

- Batch post-processing

- Report generation

- Automatic or custom results analysis

- High-quality OpenGL-based graphics

- Color or B/W vector, contour, 3D surface & particle plots

- Moving and stationary probes

- Visualization of non-inertial reference frame motion

- Measurement baffles

- Arbitrary sampling volumes

- Force & moment output

- Animation output

- PostScript, JPEG & Bitmap output

- Streamlines

- Flow tracers

- TruVOF Volume-of-Fluid (VOF) method for fluid interfaces

- Steady state accelerator for free-surface flows

- First and second order advection

- Sharp and diffuse interface tracking

- Implicit & explicit numerical methods

- Immersed boundary method

- GMRES, point and line relaxation pressure solvers

- User-defined variables, subroutines & output

- Utilities for runtime interaction during execution

- VOF to Particles

- Active simulation control

- Mesh generators

- Mesh quality checking

- Tabular properties – one or two variable dependency

- Automatic time-step control for accuracy & stability

- Automatic convergence control

- Mentor help to optimize efficiency

- Units on all variables

- Custom units

- Component transformations

- Moving particle sources

- Change simulation parameters while solver runs

- Launch and manage multiple simulations

- Automatic simulation termination based on user-defined criteria

- Run simulation on remote servers using remote solving

- Copy boundary conditions to other mesh blocks

- Shared memory computers

- Distributed memory clusters

- Particle visualization

- Velocity vector fields

- Streamlines & pathlines

- Iso-surfaces

- 2D, 3D and arbitrary clips

- Volume render

- Probe data

- History data

- Vortex cores

- Link multiple results

- Multiple data views

- Non-inertial reference frame

- Spline clip

- Built-in filters

- Cell filtering

- Plot views

- Ray tracing

- Python calculator

- Python and Batch Automation