Active Simulation Control

CFD has long played a role in product development by providing a virtual laboratory in which users are able to investigate “what if” scenarios with their designs. This has typically been a one-off approach in which a user creates an input file to represent their product design and then simulates it to understand the product’s performance. A setup typically includes geometry, material properties, flow conditions such as mass flow rates, boundary temperatures and pressures, and output frequency. Based on the resulting information learned from the simulation, various inputs may be modified and the simulation is restarted to investigate more “what if” scenarios. This approach to simulation can be thought of as “what if – then do this,” which is similar to what occurs in a closed-loop control system. Active Simulation Control provides users with complex logical triggers to define the necessary “what if – then do this” control over their simulations.

Terminology – Events/Conditions and Actions

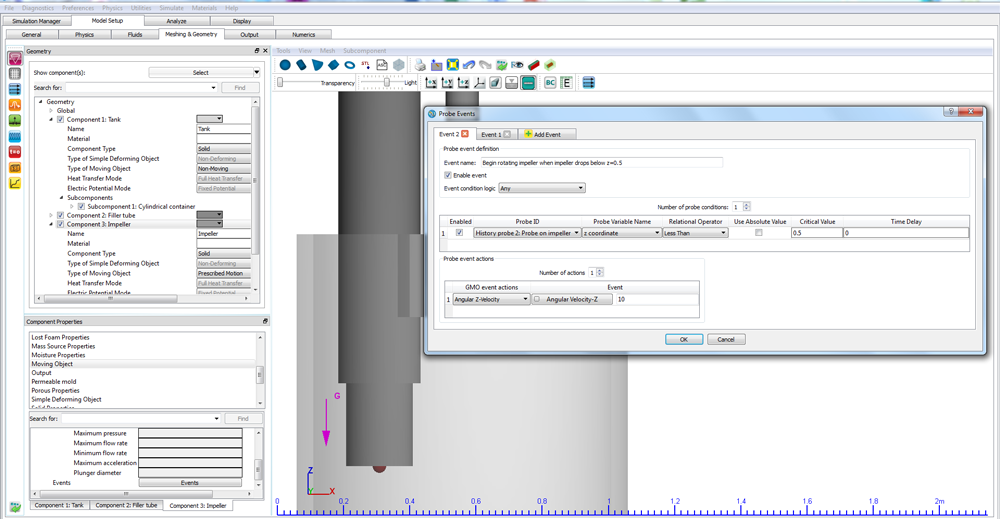

Active simulation control is based on two concepts – events/conditions and actions. Below is a brief description of each.

Events/Conditions

An event occurs when user-specified conditions at history probes, or flow information from general history data, flux surfaces, or sampling volumes are met.

Any type of probe (static probes, probes attached to GMOs, and FSI/TSE probes) can be used to define conditional checks of related variables. In some situations, surface-based and volume-based information can be more representative of the behavior of interest in simulations.

An event can consist of 1 to 10 conditions. The user can specify whether ANY or ALL of the conditions must be met in order for the event to occur. Some examples of conditions are:

- Flow depth at history probe #1 is greater than or equal to 3.25 meters

- Pressure at history probe #2 is less than 1 atmosphere

When the specified conditions are met, an event occurs and all actions associated with it are activated.

Actions

An action is a user-defined change to the simulation that is activated when an event occurs. Each event can activate one or more actions. Some examples of actions are:

- Set GMO rotation about y-axis to time-dependent values defined in an external file.

- Set y-velocity on x-min boundary of mesh block 1 to 0.0.

- Set frequency of Selected data output to 0.0 (every cycle output).

- Activate a squeeze pin in a solidification simulation.

- Terminate a simulation when the temperature in a control volume exceeds or falls below a critical value.

- Control the filling rate from a nozzle based on the turbulent energy in a sampling volume.

- Control the output frequency based the average velocity on flux planes.

When an event occurs, all actions assigned to it are activated.

Applications of Active Simulation Control

High Pressure Die Casting

Shot plunger transition to fast shot: the initial motion of the injection plunger in a high pressure die casting machine is controlled to minimize air entrainment during filling. As metal reaches the gates, the plunger motion transitions to a higher velocity to fill the casting. Active simulation control can be used to detect when metal has reached any or all of the gates and change the plunger motion accordingly. Similarly, the deceleration to prevent an impact pressure spike at the end of filling could also be triggered by metal reaching a certain position in the overflow gating.

Gravity Casting

Gravity casting often employs a pouring basin to allow a constant pressure head to be maintained over the sprue. Active simulation control can be used to control the pouring into the basin based on the fluid height in the basin.

Water/Environment

Control gates are commonly used in fish passages through dam structures to limit the flow velocity to ranges acceptable to fish. Active simulation control can be used to move the gates based on velocity information at probes located in fish resting areas.

Aerospace

The pressure in cryogenic fuel tanks must be maintained at design levels to ensure proper operation and safety. If the net pressure suction head drops below acceptable levels, cavitation will occur in the engines and the vehicle may be destroyed. Active simulation control can be used to simulate pressurization and depressurization of the system in response to a pressure loss in the vapor space.

Applying Active Simulation Control

Filling & Mixing

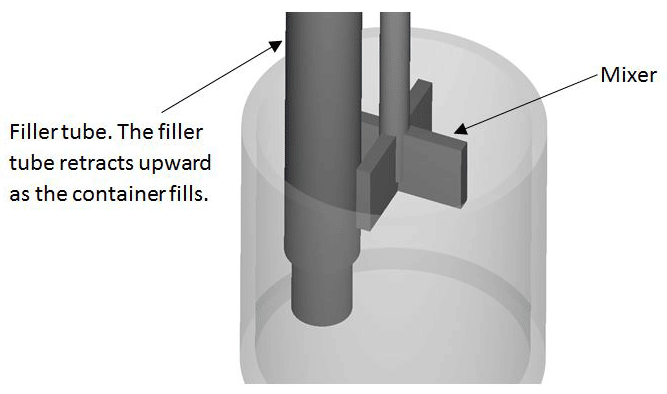

Active simulation control can be applied to a mixing simulation to control filling on/off and mixer motion. A retracting filler tube is used to fill the container with a fluid containing marker dye. A paddle mixer is lowered into the container when filling is complete:

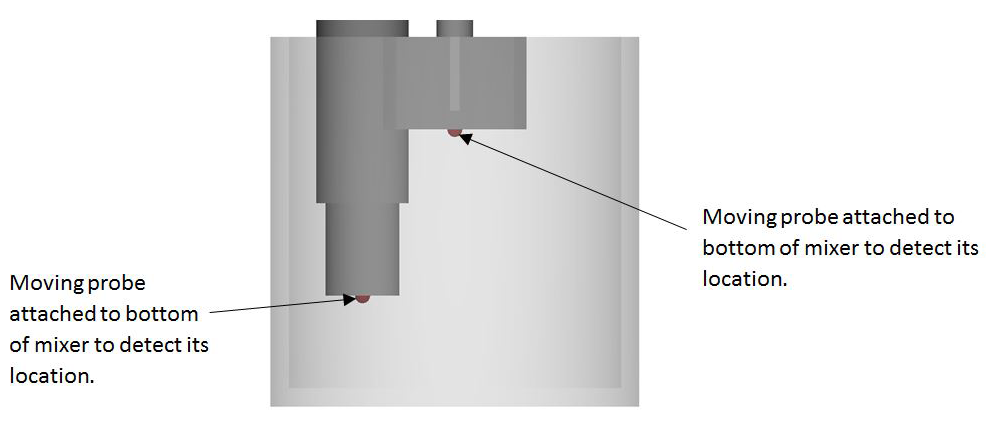

A probe is attached to the filler tube to detect its position; another probe is attached to the bottom of the mixer to detect its position:

When the filler tube is raised above a specified level, the mixing impeller begins to lower into the fluid. When the mixer reaches a specified level, it begins to rotate. When the mixer reaches a point just above the bottom of the container, it stops moving down but continues to rotate.

The animation below shows dye concentration in the fluid as the container is filled and then mixed:

Cryogenics Pump Pressurization

In this example, a pump (dark grey rectangle) in a cryogenic tank feed pipe pulls liquid oxygen from a propellant tank at a constant flow rate. As the liquid oxygen drains, a mass/momentum source (grey bar at top) is triggered by Active Simulation Control when the pressure in the ullage drops below a specified value. Pressurization is turned off when the ullage pressure rises above a specified value.

These examples offer a peek into the broad functionalities provided by active simulation control. With ASC, users are able to more closely represent the actual behavior of their designs and implement changes to their simulations actively without restarting them.