Configurable Simulation Monitor

Simulation has become invaluable in product and manufacturing process design. For example, in high pressure die casting (HPDC) process design, simulation can indicate how the dies should be cooled and/or heated to minimize the amount of time the dies must remain closed while the part solidifies. Additionally, simulation allows the runner geometry in a casting to be designed such that the metal flow reaches the gates at the same time thereby minimizing defects in the casting. By continually monitoring flow and temperature details in a simulation, defects in a design can often be identified while a simulation is still running. This allows the design to be modified quickly and allows more designs to be investigated in a shorter amount of time.

One approach to monitoring a simulation is for the user to postprocess the results frequently. For example, if the velocity of metal at some location in a casting filling simulation were of interest, the user would open the results in FLOW-3D POST and then create history plots of the flux surfaces or history probes in the region of interest. Each time the simulation results were updated (e.g., new timestep), the results would have to be reloaded and a context file applied to restore the plots of interest. This approach is simply too time consuming and cumbersome to be used effectively for monitoring simulations. The history data plotting tool on the Simulation Manager can be useful for monitoring simulations but, in previous versions, only a small, fixed set of simulation history variables could be viewed.

FLOW-3D CAST‘s Configurable Simulation Monitor expands on the capabilities of the history data plotting tool from previous versions. With the Configurable Simulation Monitor, users can add and monitor any history data in the simulation through the runtime plots.

To make the monitor view more manageable, multiple variables can be added to the same plot or to individual plots. Each plot is displayed on a separate tab so moving between plots is as simple as clicking a tab.

Configurable Plotters

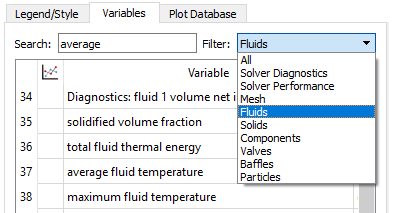

The new configurable simulation monitor can be configured to display any history variable in the simulation including simulation data for diagnostics/performance, fluid/solid-based, flux planes, valves, and history particles. Since there is often a considerable number of history data variables in a typical simulation, finding the variable of interest can be time consuming. To address this issue, a Search function has been added. The search function can be used to search for a string in a variable name so that only variables containing that string are displayed. Also, a filter on data-type can be applied. By default, all history variables are displayed. If only the data pertaining to Fluids, e.g., fluid temperature, is desired, the Fluids filter can be selected.

Plot Database

Once the runtime plotters have been configured for a simulation, the configuration can be saved to a Plot Database. When a similar simulation is set up, the plotter configuration from the plot database can be applied. This feature is a time saver when many similar simulations are run. FLOW-3D CAST is also be distributed with a predefined set of plotter configuration files for process-specific simulations.