Surface Tension

One of the earliest physics models added to FLOW-3D was surface tension. This model has been widely used over the years for many different kinds of applications, e.g., inkjets, liquid fuel behavior in zero-gravity environments, and a variety of MEMS (micro-electronic-mechanical-system) devices.

The surface tension model accurately predicts all computed surface tension forces, as well as the accuracy of adhesion forces gripping solid surfaces of arbitrary shape. Additionally, it addresses capillary pressures in porous materials and tangential surface tension forces arising from non-uniform surface tension.

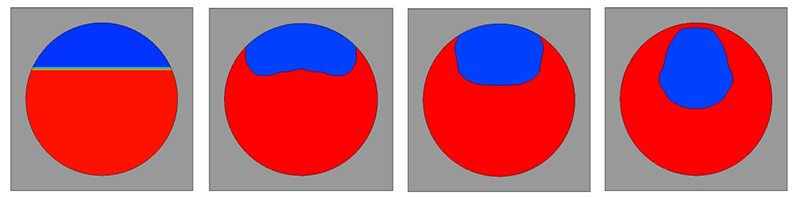

An example of the new model is the simple problem of wetting the wall of a circular contained in zero gravity. Fig. 1 shows the case of a 0.25m diameter cylinder 75% filled with water that has a zero degree contact angle with the cylinder. The bubble cleanly detaches from the wall just before 10 seconds and begins moving across the tank. The non-spherical shape is due to capillary waves propagating on the surface of the bubble.

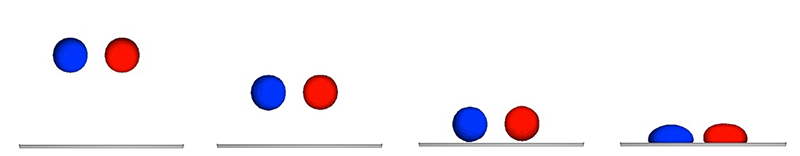

Another example is shown in Fig. 2, where two initially spherical drops of differing density (indicated by color in the plots) are moving downward toward a solid wall. The times in the plots are 0.0, 0.01, 0.02 and 0.03s. The drops have a diameter of 0.0017m, different densities, but the same surface tension coefficient of 1.872 newton/m.