Cooling Channels

Cooling channels are used in die casting and permanent mold casting for thermal management of the process to prevent the overheating of the die and to control the solidification of the casting. FLOW-3D CAST‘s cooling channel model offers a wide range of features, allowing users to accurately capture the complex behavior of the modern systems, assuring an optimum design and casting properties.

Thermal Die Cycling Simulations

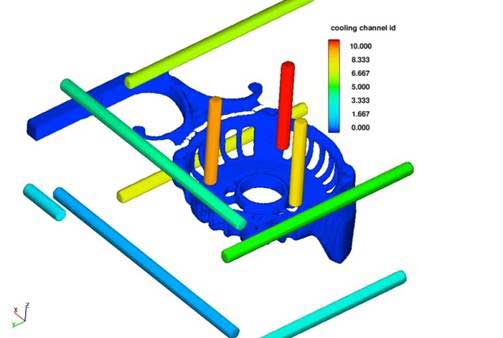

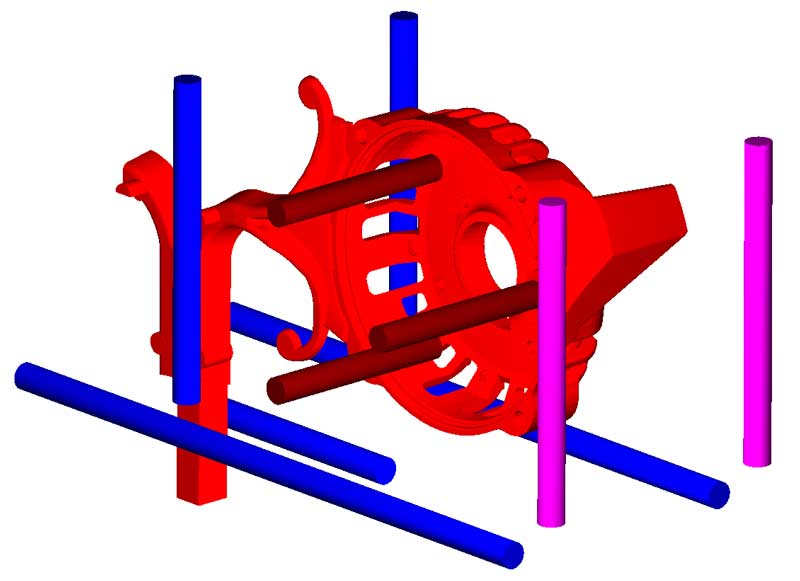

Thermal die cycling simulations are used for obtaining the die temperature after running a number of parts and a quasi-steady state condition is achieved. This type of simulation helps determine if there is sufficient cooling to extend the life of the die, and ensure no defects will occur in the final cast part. In this example, the feature of time-controlled cooling channel activation is demonstrated. Ten cycles were run where each cycle contained the following stages: after filling for duration of solidification, die opening, die spraying, and dwell time before die closes. Cooling lines in the ejector and cover of the die are on constantly while the “dead-end” cooling lines are only on during the first stage. Below is an image of the part and cooling lines with a description of duration of time on, initial temperatures, and heat transfer coefficients that were determined from equations of flow through a pipe.

This video shows a slice through the die, colored by the wall temperature, for 10 cycles. The slice was chosen to show the core cooling channels on during the first stage and off during the other stages in a cycle.