What's New in FLOW-3D CAST v5.1

Flow Science is pleased to announce the release of FLOW-3D CAST v5.1. This release provides casters with a complete simulation tool for modeling all the casting processes commonly found in modern foundries. Highlights of the FLOW-3D CAST v5.1 release include new process workspaces for investment casting, sand core making, centrifugal casting, and continuous casting, an expansive database of exothermic risers, and a brand new, chemistry-based alloy solidification model.

A major development in FLOW-3D CAST v5.1 is our new, award-winning alloy solidification model. This ground-breaking achievement provides casters with the ability to predict casting strength characteristics and reduce material usage while still meeting product safety and performance requirements.

The new process workspaces greatly reduce simulation setup and results analysis time. The Investment Casting Workspace features a fast and accurate shell mold generation tool and a full radiation model. The Sand Core Making Workspace models sand core shooting as well as all the hardening processes. The Centrifugal Casting Workspace provides the most accurate simulation tool available for all centrifugal processes. Finally, the Continuous Casting Workspace simulates all continuous casting processes including direct chill.

Additionally, databases for heat transfer coefficients, air vents, HPDC machines, and risers provide information at the users’ fingertips. The new exothermic riser database along with the solidification hotspot identification tool lets users quickly and easily place an appropriately sized exothermic riser at locations where shrinkage is predicted to occur.

State-of-the-art Solidification Model

FLOW-3D CAST v5.1 features a new, state-of-the art, chemistry-based solidification model that advances solidification modeling into the next frontier of casting simulation – the ability to predict the strength properties of castings. Using only readily-available chemical compositions of alloys, users will be able to determine properties such as ultimate tensile strength, elongation, and thermal properties such as thermal conductivity. Additionally, the new solidification model provides output such as the dimensionless Niyama criteria and micro-porosity for more accurate assessments of porosity issues.

Many factors affect the mechanical properties of a casting. These properties are primarily determined by the microstructure which is in turn determined by factors such as the solidification rate, segregation rate, and nucleation. Using the new solidification model, process designers can determine the effect of various process parameters and alloy compositions on the mechanical properties to optimize the performance of their castings to produce the highest quality, safest products possible.

Investment Casting Workspace

The Investment Casting Process Workspace is a streamlined tool for simulating investment casting processes such as filling, solidification (with either static or moving shell molds), and cooling. A shell mold creation tool allows users to quickly and reliably create a shell mold of any thickness. A wide range of controls are available for generating radiating clusters, computing view factors of participating radiating surfaces and reducing computational overhead. In castings such as turbine blades, where grain growth is controlled by directional solidification, a moving oven with a hot upper section separated by a baffle from a cooler lower section can be modeled.

Learn more about the modeled processes and features of the Investment Casting Workspace >

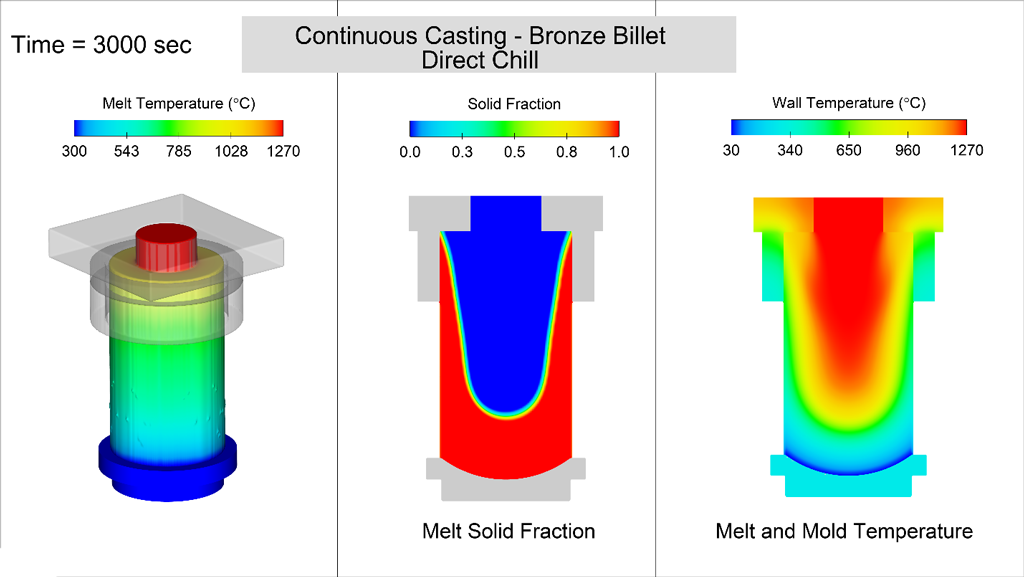

Continuous Casting Workspace

The Continuous Casting Process Workspace is a streamlined package that delivers the tools needed to model continuous billet casting and direct chill continuous casting, so casting engineers can improve their designs quickly and efficiently. Process parameters such as mold and billet cooling requirements, melt flow rate and superheat, and mold geometry can be analyzed and adjusted to minimize defects.

Learn more about the modeled processes and features of the Continuous Casting Workspace >

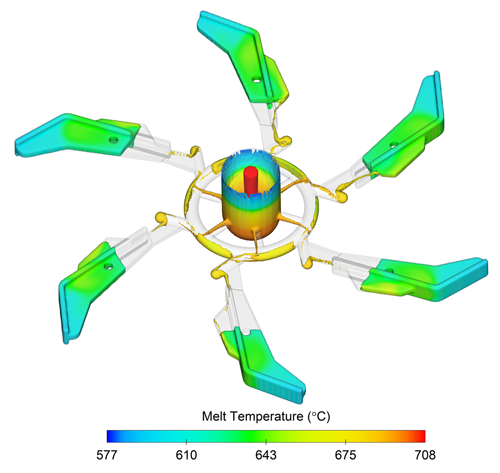

Centrifugal Casting Workspace

The Centrifugal Casting Process Workspace is an easy-to-use tool for simulating horizontal and vertical centrifugal casting, semi-centrifugal casting, and centrifuge casting. Within the process workspace, users will find all the tools they need to model their centrifugal casting process. Spinning molds and rotating meshes provide users with the flexibility to model any mold motion imaginable, as well as ladle pouring.

Cylindrical meshing offers the greatest flow modeling accuracy possible. Multi-block meshing provides even more detail to areas of high shear and large temperature gradients. Process-related defects such as excessive dross due to raining, or air entrainment during fill can be simulated. Process parameters such as mold preheat temperature, cooling requirements, and spin rates can be analyzed.

Learn more about the modeled processes and features of the Centrifugal Casting Workspace >

Sand Core Making Workspace

The Sand Core Making Process Workspace provides an easy-to-use tool for modeling the shooting and hardening of sand cores. Users can model the shooting of a wide range of sand and binder combinations to predict how a core box fills, locate regions where inadequate filling occurs, and then place and size air vents to improve filling in those regions. All core hardening processes can be modeled including cold box, hot box, and inorganic processes.

Core Hardening Processes Modeled

Cold Box

In the Cold Box process, gassing of sand cores with amine gas can be simulated. The placement of appropriately sized air vents is essential to ensure that the concentration of amine gas throughout the core is adequate to harden the core.

Hot Box

The Hot Box hardening process uses energy from the heated core box to heat the shot sand core.

Inorganic

The Inorganic hardening process uses hot, relatively dry air blown through the shooting inlets to dry the binder. As hot air is passed through the core, the binder is evaporated and is carried out of the core box through the air vents. Proper sizing and location of air vents ensures that enough air flows through all regions of the core.

Air vent database

A wide variety of air vents are available in FLOW-3D CAST’s air vent database.

Exothermic Sleeves

A common issue in large castings is shrinkage in solidifying regions due to inadequate feeding of liquid metal. The solution to this problem is to attach risers to the casting where hot spots are located so that the solidifying regions can pull liquid metal. The hot spot feature in FLOW-3D CAST provides a quick indication of the hot spot locations as well as the thermal modulus of the hot spot.