Improving Clarifier Performance

Thanks to Mr. Earle Schaller and Dr. John Richardson for contributing this material.

When NEFCO engineers sought to refine their procedures used to design their Density Current Baffle Systems, they developed a comprehensive analysis approach based on experience, the results of field studies and state-of-the-art modeling computer modeling.

Background

Circular activated sludge secondary clarifiers rely on gravity to settle out solids and produce clear effluent. However, circular clarifiers are almost universally affected by the short-circuiting that is caused by density currents that are developed within the tank. Density current baffles mounted inside the clarifier have been found to be the most effective means of minimizing the effects of short-circuiting and improving effluent quality. The Stamford Density Current Baffle is the most common type of baffle in use today. NEFCO, Incorporated produces engineered fiberglass products for the water & wastewater treatment industry. The company pioneered the design and development of the Stamford Baffle and is the world’s leading supplier of these baffle systems.

NEFCO’s approach to baffle design begins with sizing algorithms that have been developed and refined over the past twenty years coupled with extensive field studies. These efforts have enabled the company to design baffles for a variety of standard and non-standard clarifier configurations. Most recently, NEFCO used the computational modeling power of FLOW-3D to further extend its understanding of baffle dynamics and to develop new baffle design strategies. Our civil and environmental customers now use FLOW-3D HYDRO for these types of modeling and analysis.

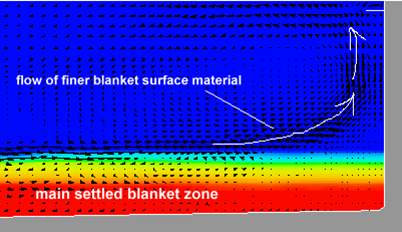

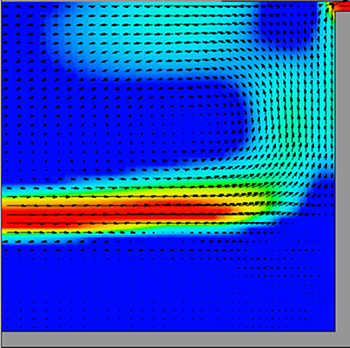

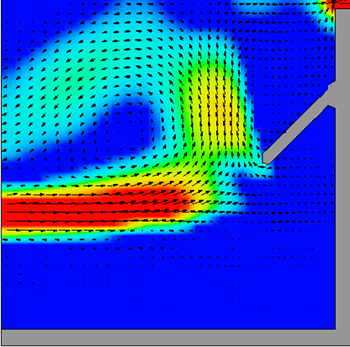

Studies by the Environmental Protection Agency (EPA) and others show that density currents form in all activated sludge secondary clarifiers, regardless of size or shape, and have significant adverse effects on clarifier performance. These currents often develop when the dense influent cascades to the bottom of the tank, creating relatively high velocity disturbances. These disturbances, or density currents, move in a horizontal plane, just above the sludge blanket, picking up lighter solids and short-circuiting the main clarification volume of the tank. The density currents then travel up the tank walls transporting these lighter solids to the effluent. The result is a significant increase in total suspended solids (TSS) and a dramatic reduction in retention time.

A Picture is Worth a Thousand Words

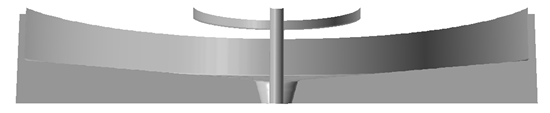

NEFCO, working in conjunction with Blue Hill Hydraulics and using FLOW-3D HYDRO, developed a three-dimensional model of a 70-foot circular clarifier to study the performance of a Stamford Density Current Baffle System. A cutaway view of the clarifier is shown below, along with its basic dimensions.

Flow patterns and solids distribution within the clarifier were computed based upon a variety of Density Current Baffle parameters including baffle length, inclination angle and vertical position.

| Tank Diameter | 70 ft |

| Side Water Depth | 10 ft |

| Bottom Slope | 1:12 |

| RAS Well Diameter | 6 ft |

| Inlet Pipe Diameter | 2 ft |

| Influent Baffle Diameter | 23 ft |

| Effluent Launder Type | Outboard |

Solutions that Work

The NEFCO Stamford Density Current Baffle System is specifically designed to intercept and redirect the flow of density currents in the tank back for the main clarification volume of the clarifier. This engineered system increases hydraulic capacity and produces as much as a 50% reduction in total suspended solids. The FLOW-3D HYDRO analyses confirm NEFCO’s baffle design algorithms and provide unique insights into baffle performance that NEFCO is incorporating into its newest baffle design strategies.

Learn more about modeling water & environmental applications using FLOW-3D HYDRO.