Hydraulic Jump in a Trench Type Pump Sump

This article was contributed by Steve Saunders, Principal at the Ibis Group

Hydraulic jumps are a flow phenomenon familiar to people working with open channel applications. Wikipedia defines a hydraulic jump as “a condition where open channel flow abruptly transforms from super- to sub-critical.” At the location where the jump occurs, one can observe velocity head getting traded for a step-up in water surface elevation. In flow control applications like spillways, hydraulic jumps are set up intentionally as a means of dissipating energy to mitigate erosion. They also come into play for recreational purposes. The standing waves created by hydraulic jumps are used to train surfers how to ride in surf parks that can be thousands of miles from any ocean. A novel application for hydraulic jumps is in self-cleaning trench type pump sumps where the energy transfer of the jump resuspends and carries away solids that have settled out during normal pumping operations.

Simulating a Trench Type Sump Pump

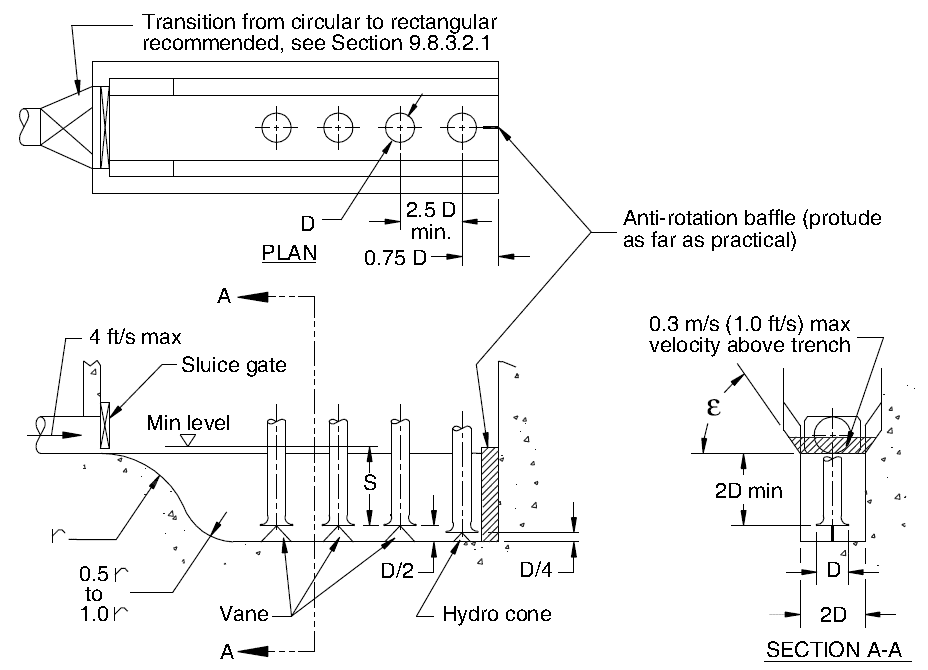

FLOW-3D HYDRO has proven to be a reliable tool in simulating hydraulic jumps and has been put to use in the design and demonstration of a self-cleaning trench type pump sump. The trench type pump sump comprises a narrow channel with a line of pump intakes. A typical application is storm water collection where no inlet screens are present to strain out grit and gravel from the incoming water. An example is presented in the schematic below.

This figure is taken from the ANSI/HI 9.8 Pump Intake Design manual and shows plan and elevation views of a sump with four pumps installed. The arrangement of the inflow culvert, sump floor and pump suction off-floor elevations is critical to the self-cleaning capability of this design type. Take note that the inflow culvert is at an elevation higher than the minimum operating sump water level. Also, the trench wall at the inflow end has an ogee shape. Finally, the pump intake bell at the far (right) end of the trench is set an elevation half of that of the upstream pumps.

Designing for Storm Events

After a storm event, grit and gravel settle on the sump floor. They get re-suspended and drawn off by means of a progressive hydraulic jump. During a cleaning cycle, the water is drawn off by the lower pump at the far end of the trench at a higher rate than is entering through the inflow culvert. As the water drops below the minimum normal operating level, the inflow accelerates down the ogee-shaped wall and ultimately becomes supercritical. Once the water level in the sump nears the floor, a hydraulic jump forms and progresses along the sump until the lower far end pump loses its suction. You can observe this taking place in the animation below.

During this sequence, the hydraulic jump performs two important roles. The supercritical portion upstream of the jump scours the sump floor of grit and gravel thereby re-suspending it to be pumped away. A glance at the color scale in the animation will tell you that the scour velocity at the base of the ogee nears about 9 ft/sec. Meanwhile, the stepped-up water elevation downstream of the jump provides the lower end pump with sufficient submergence to continue operating until the sump is pumped out.

The Magnolia Storm Water Pumping Station

Using FLOW-3D HYDRO for this self-cleaning sump application means the trench geometry can be readily adjusted to optimize the action of the hydraulic jump. The Magnolia Storm Water Pumping Station in El Paso, Texas originally used FLOW-3D as a design and evaluation tool. Our civil and environmental customers now use FLOW-3D HYDRO for these types of modeling and analysis. Commissioned in 2016, the Magnolia Storm Water Pumping Station was constructed to eliminate the flooding of Interstate 10 during heavy rain events. The Magnolia station comprises three large vertical turbine pumps in a self-cleaning trench type sump. During the sump design process, several geometry variations were evaluated with FLOW-3D HYDRO thus arriving at a configuration ideal for pump operational efficiency and ease of maintenance by way of its self-cleaning capability.