FLOW-3D is a powerful modeling tool that gives engineers valuable insight into many physical flow processes. With special capabilities for accurately predicting free-surface flows, FLOW-3D is the ideal CFD software to use in your design phase as well as in improving production processes.

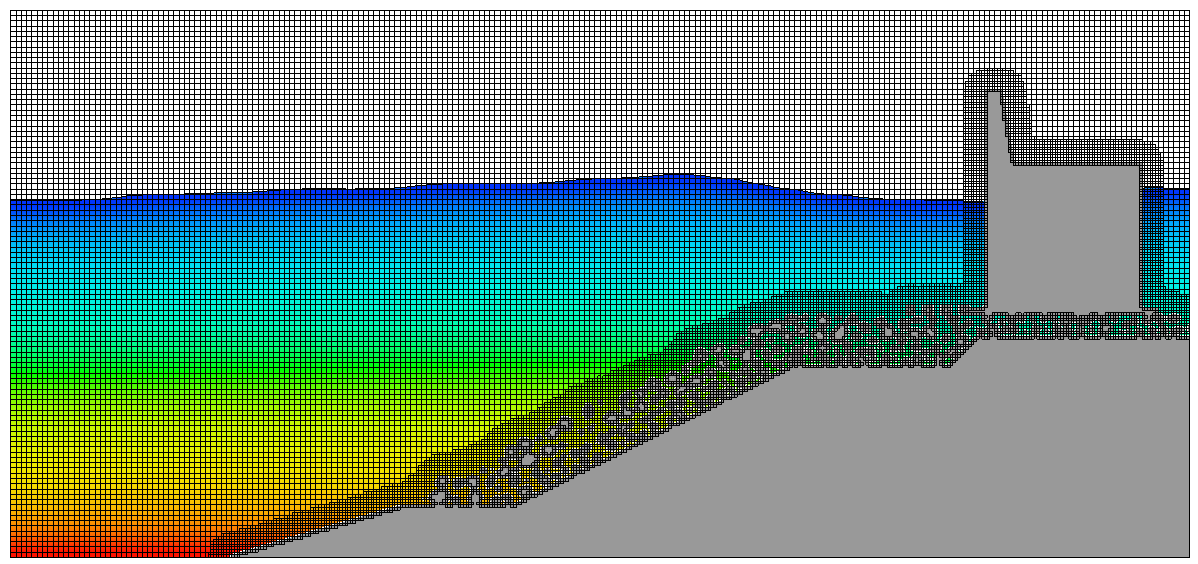

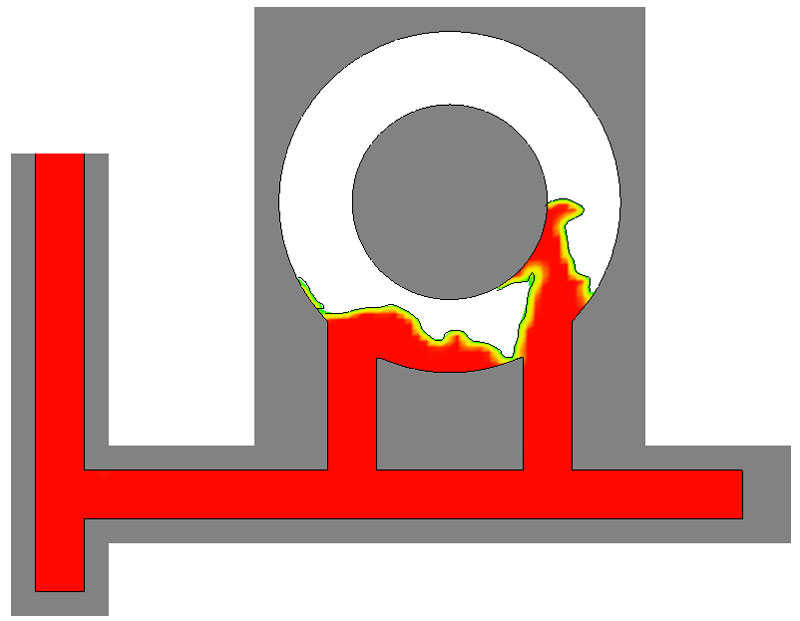

TruVOF and Free Surface Modeling

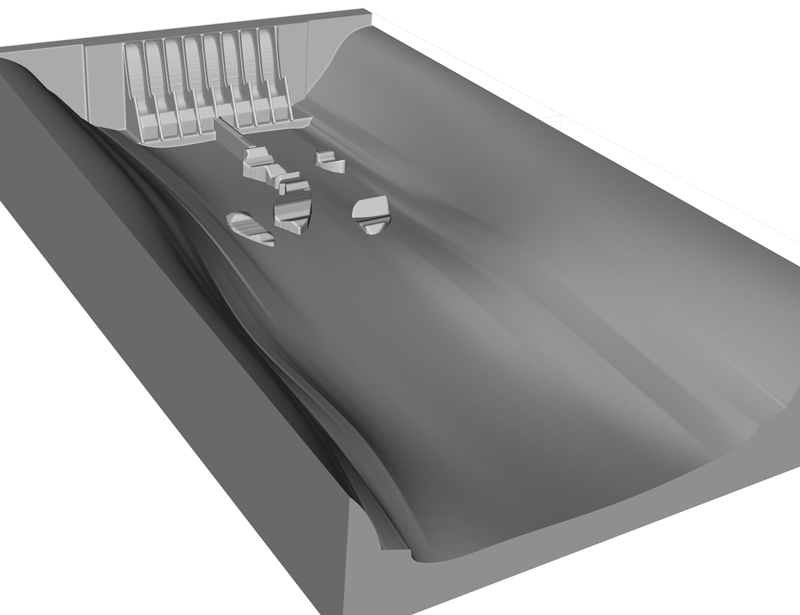

FLOW-3D differs from other computational fluid dynamics software in its treatment of flowing fluid surfaces. The program uses special numerical methods to track the location of surfaces and to apply the proper dynamic boundary conditions at those surfaces. In FLOW-3D, free surfaces are modeled with the Volume of Fluid (VOF) technique that was first developed by a group of scientists, including Flow Science’s founder, Dr. C. W. Hirt, at the Los Alamos National Laboratory. A number of competing CFD programs claim to have incorporated a VOF capability, when in reality they implement only one or two of the three fundamental VOF ingredients. Prospective users of CFD should be aware that these pseudo-VOF schemes will often give incorrect results. FLOW-3D has all of the ingredients recommended for the successful treatment of free surfaces. Moreover, FLOW-3D incorporates major improvements beyond the original VOF method to increase the accuracy of boundary conditions and the tracking of interfaces. We refer to our implementation as TruVOF. Read more about FLOW-3D‘s TruVOF method in CFD-101

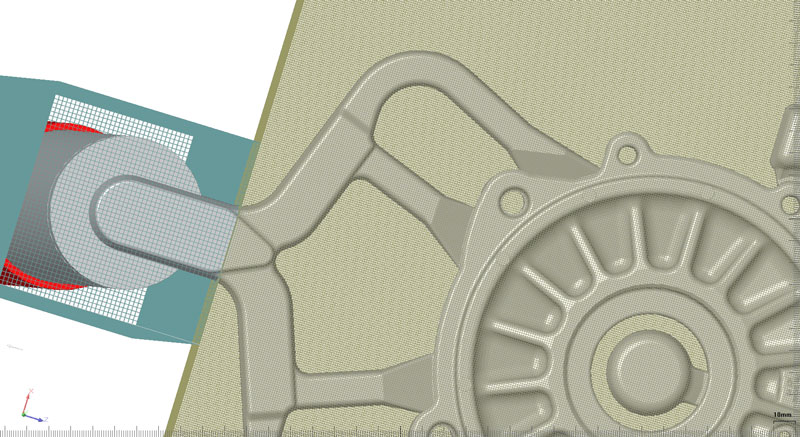

Free Gridding Separates Meshing from Geometry Construction

FLOW-3D’s basic approach to gridding combines the advantages of simple rectangular grids with the flexibility of deformed, body-fitted grids. Fixed grids of rectangular control elements are simple to generate and possess many desirable properties (e.g., improved accuracy, smaller demands on memory, and simpler numerical approximations). The approach is referred to as “free-gridding” because grids or geometry can be freely changed, each independent of the other. This feature eliminates the tedious task of generating body-fitted or finite-element grids.

The flexibility and efficiency of rectangular gridding are enhanced by the advanced features such as multi-block and conforming meshing. Linked, nested and partially-overlapping mesh blocks provide the means to effectively enmesh complex, multi-scale flow domains and concentrate high resolution in the areas of interest. Conforming meshes allow users to generate high quality grids that conform to specific geometric shapes or cavities, resolve thin structures and boundary layers, without the limitations typically associated with structured rectangular gridding. Read more about FLOW-3D‘s free-gridding approach in CFD-101

Modeling Fluid Flow in Complex Geometry is Easy with FAVOR™

FLOW-3D incorporates a special technique, known as the FAVOR™ (Fractional Area Volume Obstacle Representation) method, which is used to define general geometric regions within the rectangular grid. The philosophy behind FAVOR™ is that numerical algorithms are based on information consisting of only one pressure, one velocity, one temperature, etc., for each control volume, so it would be inconsistent to use much more information to define the geometry. Thus, the FAVOR™ technique retains the simplicity of rectangular elements while representing complex geometric shapes at a level consistent with the use of averaged flow quantities within each volume element. Read more about FLOW-3D‘s FAVOR™ technique in CFD-101

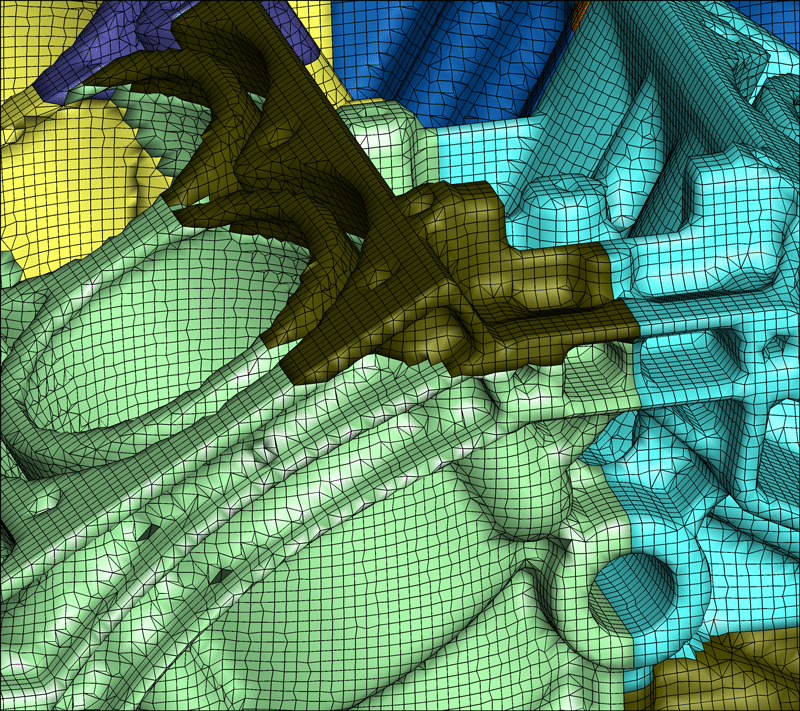

Meshing Capabilities

FLOW-3D offers a multitude of meshing capabilities that are designed to be simple yet efficient and robust in modeling complex flows. While the simplicity of meshing can be attributed to the structured mesh that is used by FLOW-3D, the efficiency and robustness is achieved by various features enabled by multi-block meshing. The use of multiple mesh blocks allows local refinement in areas of interest and significantly reduces computational resources required for a given simulation. Small obstacles, complex geometries and thin channels that are small compared to the overall domain size can be accurately resolved using one of the several multi-block meshing capabilities such as; linked, nested, conforming, and/or partially overlapping mesh blocks. Linked mesh blocks can be used only to mesh the areas of interest and limit the total number of computational cells. Nested mesh blocks can be used to enhance the resolution around an area of interest. Conforming and partially overlapping mesh blocks can be used to resolve irregularly shaped fine features with sharp changes in scale that otherwise cannot be simply resolved using nested mesh blocks. FLOW-3D also allows body-fitted finite element meshes to model Fluid-Structure Interaction. These body-fitted meshes can be automatically generated with FLOW-3D or imported from external CAD packages. All these meshing techniques gives users the flexibility to create meshes that are simple and yet efficient, thereby improving solver performance and reducing simulation turnaround time.