FLOW-3D’s capabilities with respect to free surface hydrodynamics, wave generation, moving objects, mooring lines and welding processes make it an extremely well-suited tool to model CFD processes in the marine and maritime industry.

Modeling Moving Objects

FAVOR™ is a unique, cartesian fixed-mesh method for handling geometry. This method allows for moving object dynamics to be modeled without the need for a moving/deforming mesh, reducing simulation runtimes while maintaining accuracy. The moving objects model gives the user the flexibility of tracking vessel motion using either an explicit or an implicit method. FLOW-3D‘s Immersed Boundary Method allows for highly accurate predictions of forces on fixed and moving objects. This simulation shows the complex, fully-coupled motion of an LNG tanker moving in waves.

Mooring Lines, Springs & Ropes

Special objects in FLOW-3D (such as mooring lines and springs) when attached to other moving objects, allow engineers to accurately capture vessel dynamics during ship launches, floating barrier dynamics, buoys, wave energy converters, etc. In this ship launch example, a ship slides down a slipway and into the water. The motion of the ship is constrained by mooring lines, which prevents it from floating off downstream. Simulation courtesy of Eastern Shipbuilding.

Welding

With the addition of FLOW-3D WELD, welders in the shipbuilding industry can minimize welding defects such as porosity, significantly increasing the quality of their hulls while optimizing production times.

Offshore Structures

Loads on marine offshore structures are largely determined by the detail of wave structure interactions in random sea states. FLOW-3D allows users to model non-linear interactions between floating structures under a variety of wave types and sea spectra, including JONSWAP, Pierson Moskowitz, and custom wave energy profiles. FLOW-3D provides green water (water on deck) presence analysis, impact loads, and fully non-linear wave propagation analysis, as well and structure response in wave – structure – mooring systems. In addition to fixed pile structures, FLOW-3D can be used to simulate the forces on floating structures, such as the dock shown here. The movement of the dock is stabilized using the mooring lines model, and the dynamics of the dock as a result of a steadily increasing water level can be seen in this video.

Simulating Wave Impacts on Offshore Platforms

The calm-water air gap under offshore platform decks is a critical design parameter and is determined by the required minimum air gap in extreme design conditions. FLOW-3D can be used to effectively in the prediction of air gap and wave impact loads on offshore platforms, tension leg platforms and semi-submersibles. By modeling problems at full scale in the numerical environment, FLOW-3D allows engineers to by-pass the often delicate scaling issues associated with reduced-scale model physical basin testing.

Planing Hulls & Ship Motion

Flow around the hulls of ships is an important focus for naval architects. Many aspects of the flow past the hull need to be examined, including the resistance (drag), stern boundary layer, streamwise vortices, and velocity field at the propeller plane. FLOW-3D‘s Moving Objects Model allows naval architects to model the behavior of hulls in displacement, semi planing or planing regimes, as well as the transients of hulls accelerating onto the plane. FLOW-3D‘s natural strengths modeling free surfaces allows engineers to accurately predict the pressure field acting on a hull even in large amplitude wave or high speed regimes, where slamming forces too can be evaluated.

The hydro-dynamic response of a planing hull is analyzed in three distinct regimes that are demonstrated in this series of simulations. The first simulation shows the ‘rise to the plane’ stage during which the motor yacht accelerates until the hydrodynamic forcing is sufficient to effectively lift the yacht above the water. The second simulation shows the yacht cruising on flat water at 40 knots, and the third simulation shows the response of yacht at high speeds with an incoming wave field.

Sloshing & Slamming

This simulation shows the complex, fully-coupled motion of an LNG tanker moving in waves, as captured by FLOW-3D. The sloshing of fluid in the tanks affects the dynamics of the vessel, which contains bilge keels and a bulbous bow to help it maintain stability in incident waves. Notice also that the fluid sloshing in the tanks has a phase shift from the motion of the ship, as expected. The moving object model, the density evaluation model and the wave generation boundary conditions in FLOW-3D can assist maritime engineers in analyzing similar problems.

Maritime Case Studies

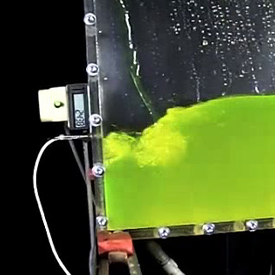

Validation of Sloshing Simulations in Narrow Tanks

Validation of Sloshing Simulations in Narrow Tanks This case study was contributed by Peter Arnold, Minerva Dynamics.The objective of this work...

Earthrace: Speed, Fuel Efficiency and Safety

Earthrace: Speed, Fuel Efficiency and Safety Earthrace is a wave-piercing 78 ft. trimaran powerboat designed to circumnavigate the world fueled...