FLOW-3D AM

An advanced simulation software, FLOW-3D AM analyzes and predicts melt-pool dynamics and solidification in AM processes such as laser powder bed fusion (LPBF) and directed energy deposition (DED). Built on a robust CFD engine, FLOW-3D AM incorporates high-fidelity solutions for conductive, convective, and radiative heat transfer, laser and particle physics, and Marangoni effects for predicting complex phenomenon at the micro and meso scales. FLOW-3D AM makes it easy for scientists and engineers to evaluate process parameters for various alloys under a range of environmental conditions allowing them to predict defects such as keyhole porosity and lack of fusion, as well as saving them time and costly material incurred from running experiments. Researchers can also predict cooling rates and thermal gradients for feeding into microstructure and residual stress solvers, gaining valuable insights on material integrity and performance that are often impossible from experimentation alone.

What Product is Right for You?

FLOW-3D AM

This is a combination of FLOW-3D DEM and FLOW-3D WELD that lets you simulate the end-to-end laser powder bed fusion process including the powder spreading and the laser melting process.

FLOW-3D WELD

Simulate the laser-powder bed interaction in a laser powder bed fusion process and the laser-wire feed or the laser-powder feed interaction in a directed energy deposition process. Additionally, simulate laser welding, laser cladding, laser soldering and laser brazing applications.

FLOW-3D DEM

Simulate the powder bed formation process for laser powder bed fusion or binder jetting processes. Additionally, simulate binder impingement on a powder bed and other fluid flow related applications not related to a laser.

FLOW-3D

Simulate the fused deposition modelling process and binder impingement in a binder jetting process. Additionally, simulate other fluid flow simulations not related to a laser.

Laser Powder Bed Fusion (LPBF)

Many aspects of the LPBF process can be better understood and optimized through CFD simulations.

Particle Spreading

The first step in a LPBF process is depositing a powder bed of certain material with prescribed layer height and desired powder bed density. FLOW-3D DEM enables researchers to understand powder spreading and compaction as it relates to powder size distribution, material properties, cohesion effects, as well as geometry effects such as roller or blade motion and interaction. These simulations give an accurate understanding on how process parameters affect powder bed characteristics such as packing density that will have a direct impact on the melt-pool dynamics in the subsequent printing process.

Melting

Once the powder bed is generated in a FLOW-3D DEM simulation, it is extracted as an STL file. The next step is simulating the laser melting process using CFD. Here, we model the interaction of the laser beam and the powder bed. To capture this process accurately, the physics include viscous flows, laser reflections within the melt pool (through ray tracing), heat transfer, solidification, phase change and vaporization, recoil pressure, shield gas pressure and surface tension. All of these physics have been built on top of the TruVOF method to accurately simulate this complex process.

Multilayer

Once the melt pool track solidifies, FLOW-3D DEM can be used to simulate the spreading of a new powder layer on the previously solidified layer. Similarly, laser melting can then be performed on the new powder layer to analyze fusion conditions between subsequent layers.

When depositing and melting subsequent layers with LPBF, temperature gradients, cooling rates, and solidification will have a major impact on the fusion between layers, the microstructure, and the final part quality. FLOW-3D AM enables researchers to run high-fidelity simulations at the melt-pool scale of both powder physics and laser-material interactions to understand the resultant fusion, thermal profiles, and solidification from depositing additional layers. Further, researchers can look at the effect of scan strategy on subsequent layers to optimize laser parameters to increase production without compromising part quality.

Keyholing in LPBF

How is porosity formed during keyholing? This was the question that researchers from TU Denmark answered using FLOW-3D AM. As the substrate melts under the application of a laser beam, the recoil pressure due to vaporization and phase change depresses the melt pool. The co-existence of a downward flow due to recoil pressure and the additional laser energy absorption due to laser reflections causes a runaway effect, transitioning the melt pool into a keyhole. Eventually, due to the varying temperature along the keyhole wall, surface tension forces cause the wall to pinch off and result in voids that can get trapped by the advancing solidification front, resulting in porosity. FLOW-3D AM has all the necessary physics models to simulate keyholing and porosity formation in laser powder bed fusion processes.

Scan Strategy

Scan strategies have a direct impact on microstructure due to their influence on temperature gradients and cooling rates. Researchers are using FLOW-3D AM to explore optimal scan strategies to understand the remelting that occurs between tracks which can influence defect formation and the microstructure of the solidified metal. FLOW-3D AM gives full flexibility in the implementation of time-dependent directional velocities for one or multiple lasers.

Beam Shaping

In addition to laser power and scan strategy, the laser beam shape and heat flux distribution have a large influence on the melt-pool dynamics in an LPBF process. AM machine makers are exploring the use of multi-core and arbitrary-shaped laser beams on process stability and throughput. FLOW-3D AM allows for the implementation of multi-core and arbitrary shaped beam profiles, helping provide insights into the best configurations for increasing production and improving part quality.

For an in-depth look at some of the work that has been done in this area, watch our “The Next Frontier of Metal AM” webinar.

Multi-material Powder Bed Fusion

In this simulation, the stainless steel and aluminum powders have independently-defined temperature dependent material properties that FLOW-3D AM tracks to accurately capture the melt pool dynamics. The simulation helps with understanding material mixing in the melt pool.

Microstructure Prediction

FLOW-3D AM data such as cooling rates and temperature gradients can be input into microstructure models to predict the crystal growth and dendrite arm spacing.

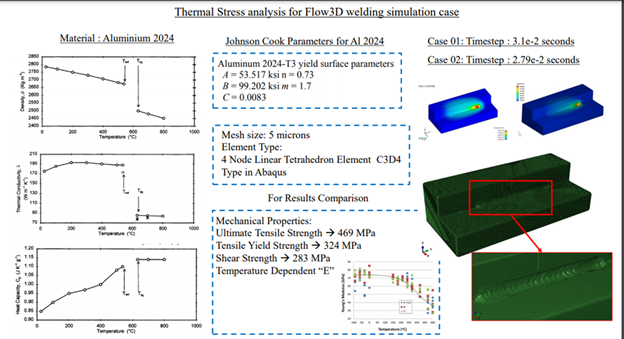

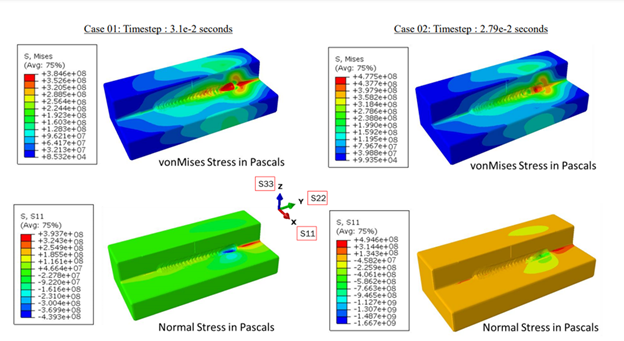

Thermal Stresses

Results from a FLOW-3D AM simulation can be input into FEA software such as ABAQUS or MSC NASTRAN to run further thermal stress analysis. Here, you can see how results from a laser welding simulation of a T-joint are imported into ABAQUS for further stress analysis. Similarly, results from the solidified melt pool data in an LPBF simulation can be used to study thermal stress and distortion analyses in other FEA software.

Directed Energy Deposition

Directed Energy Deposition (DED) is an additive manufacturing process that builds parts by depositing either a wire or powder that is heated and fused together using an energy source such as a laser or an electron beam. FLOW-3D AM can simulate the DED process by accounting for process parameters such as powder or wire feed rates and size characteristics, and laser power and scan speeds. Additionally, a multi-material DED process can be simulated by defining independent thermophysical material properties for different alloys in the substrate and the powder material.

With the implementation of laser physics as well as heat transfer, solidification, surface tension, shield gas effects, and pressure effects including recoil pressure, researchers can accurately analyze the effects of process parameters on the strength and uniformity of the resulting weld bead. Additionally, these simulations can be extended to multiple layers to analyze fusion between subsequent layers.

Powder-Based DED

Powder-based DED is a highly accurate and controllable method for depositing powders to make 3D parts layer by layer. With this flexibility comes a wide variety of process parameters to consider when choosing process parameters to optimize production and reduce material waste. FLOW-3D AM allows for full consideration of powder composition (up to two different materials), catchment efficiencies, build directions and laser and substrate orientation.

Wire Based DED

Wire-based DED tends to have higher throughput and less waste than powder-based DED, but there is less flexibility in terms of material composition and deposition orientations. FLOW-3D AM is useful for understanding the processing windows for wire-based DED and allows for optimization studies to find the best processing parameters such as wire feed rate and diameter for a build.

Wire Powder-Based DED

Some researchers are looking into hybrid wire powder-based DED systems which open a wider range of processing conditions for building parts. As an example, this simulation is looking at a hybrid system with variable powder and wire feed rates.