The ability to visualize and present clear, meaningful analysis of simulation data is a crucial part of the CFD simulation process. FLOW-3D POST provides all the necessary tools to effectively communicate your simulation findings. In this blog, we’ll explore some powerful features of FLOW-3D POST so that you can communicate your CFD results with confidence.

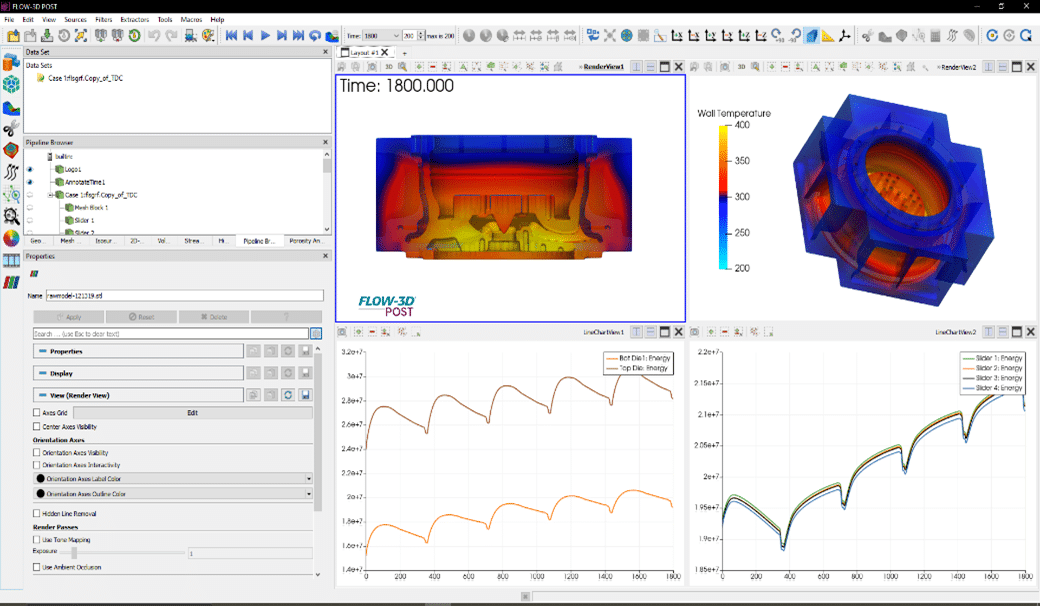

Here is an example of an aluminum wheel casting, simulated using the low pressure die casting workspace in FLOW-3D CAST. The objective of this simulation is to find the steady state thermal condition within the mold. Thermal die cycling is used to visualize mold performance and ensure that there is a proper thermal gradient in the mold before beginning the filling simulation. This image shows a few easily accessible features in FLOW-3D POST.

Using multiple viewports allows the user to get a complete visualization to examine areas and features of interest. This is also useful when wanting to compare multiple designs. Notice that the top left viewport is using a 3-dimensional slice; 2D and 3D slicing options allow the user to visualize the internal features of geometries and flow systems.

The bottom viewports show a graphical output of history data based on the thermal energy transferred to the mold components.

The legend and annotation properties are fully customizable, allowing you to label and display your data clearly and effectively. Additional features shown here include a customized color scale and opacity setting for the mold visualization.

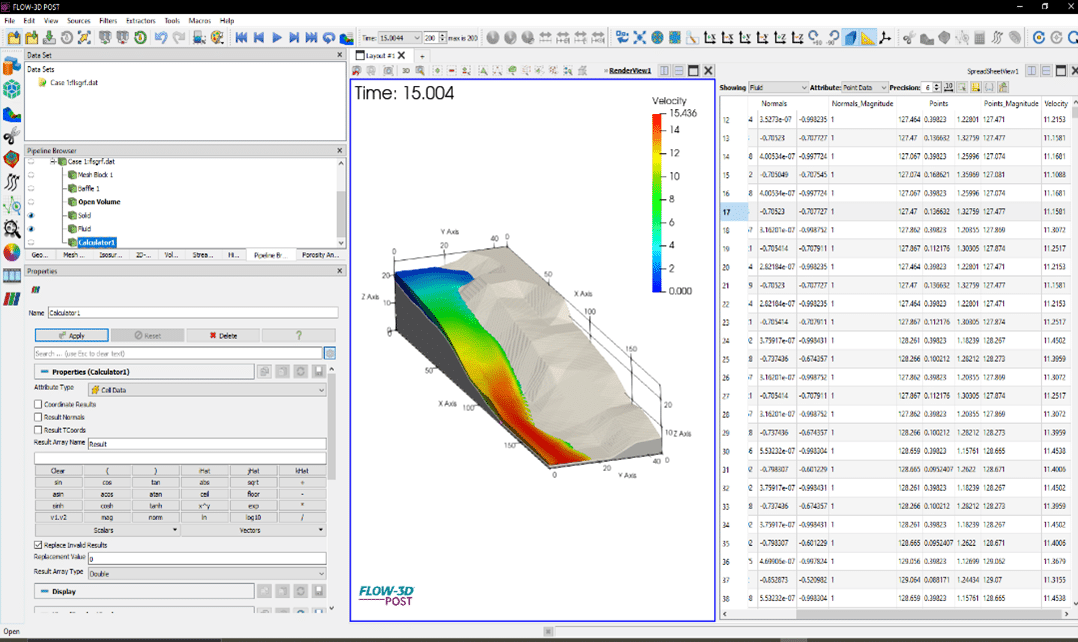

As we go deeper into the functionality of FLOW-3D POST we see some powerful ways to extrapolate information. In this tailings breach example, we can see the use of a spreadsheet data view on the right. Here, data from individual cells can be highlighted and isolated, helping the user illustrate flow features at a mesh cell-level of precision. In the panel on the left, we can see the calculator function, which can be used to manipulate history data on the fly. If quick decision-making is important to the project, built-in capabilities such as exporting data for statistical analysis can provide macro- and micro-level viewpoints of the results efficiently.

Stay tuned! We will be diving into some of the new features including ray tracing, cell-level data extrapolation, and key framing. In the meantime, go to our FLOW-3D POST product page to see some of examples of how powerful of a tool FLOW-3D POST is.

At Flow Science we develop innovative solutions that help our customers conceptualize, create, and analyze their simulations with confidence. If you would like more information or a personal demonstration of any of our FLOW-3D products and FLOW-3D POST, please contact us at webdemo@flow3d.com.