Low Pressure Die Casting Workspace Highlights

- Pressure controlled filling for absolute fill accuracy

- Full process modeling includes void, venting and back-pressure effects

- Advanced solidification and heat transfer control for precise early freezing and solidification defects like porosity

Workspace Overview

The Low Pressure Die Casting Workspace is an intuitive modeling environment designed for engineers to successfully model low pressure die casting applications with FLOW-3D CAST. Flexible pressure controls allow engineers to accurately reproduce pressure, venting and backpressure conditions in order to deliver a complete analysis of fill, air entrapment and porosity defects. Die thermal management and state-of-the-art solidification models seamlessly connect to the fill through the workspace’s sub-process architecture. The Low Pressure Die Casting Workspace provides a complete and accurate solution for all aspects of the simulation in a simple yet versatile modeling environment.

Low Pressure Die Playlist

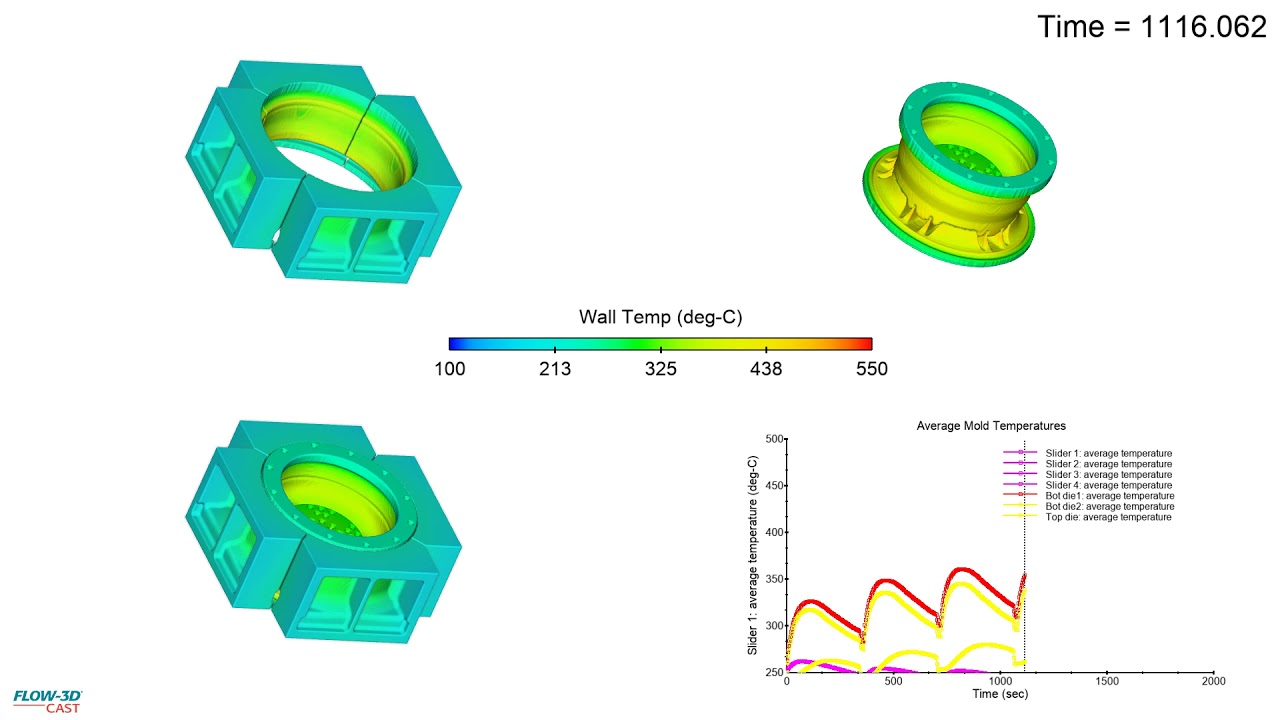

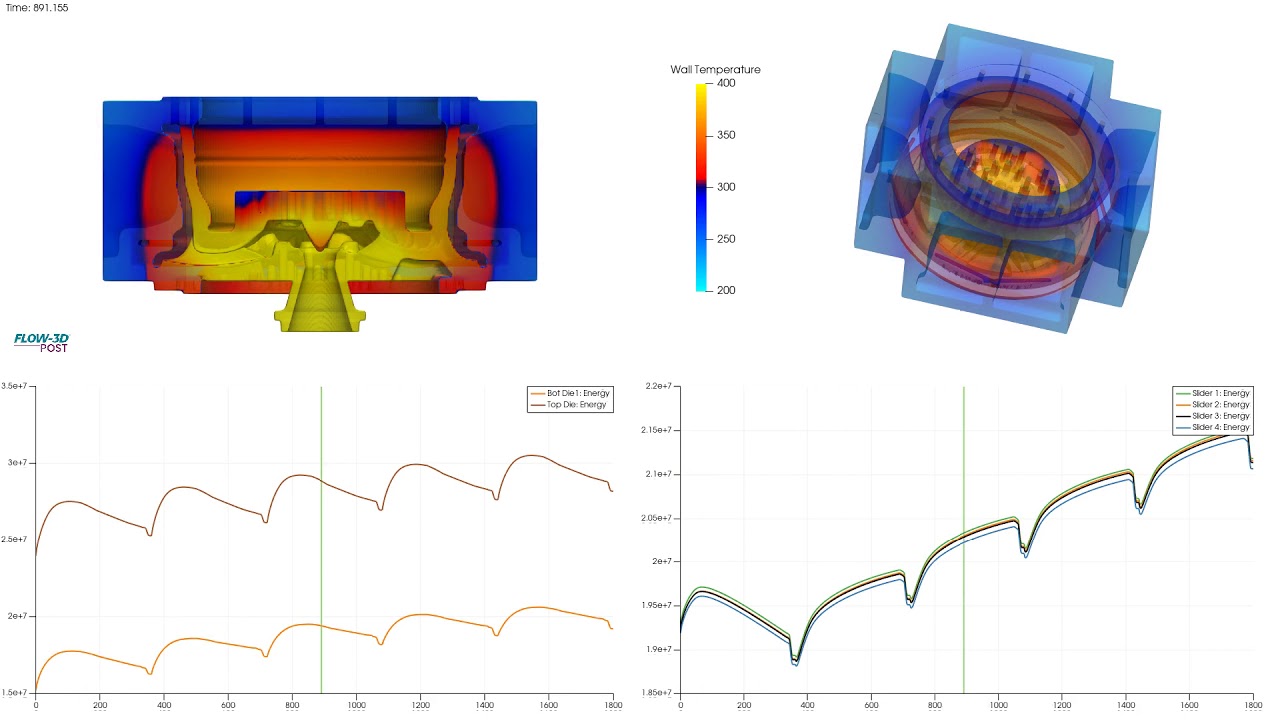

This FLOW-3D CAST low pressure die casting simulation shows a thermal die cycling of an aluminum wheel die. This type of simulation is used to analyze the thermal saturation in the sliding and closing of the dies.

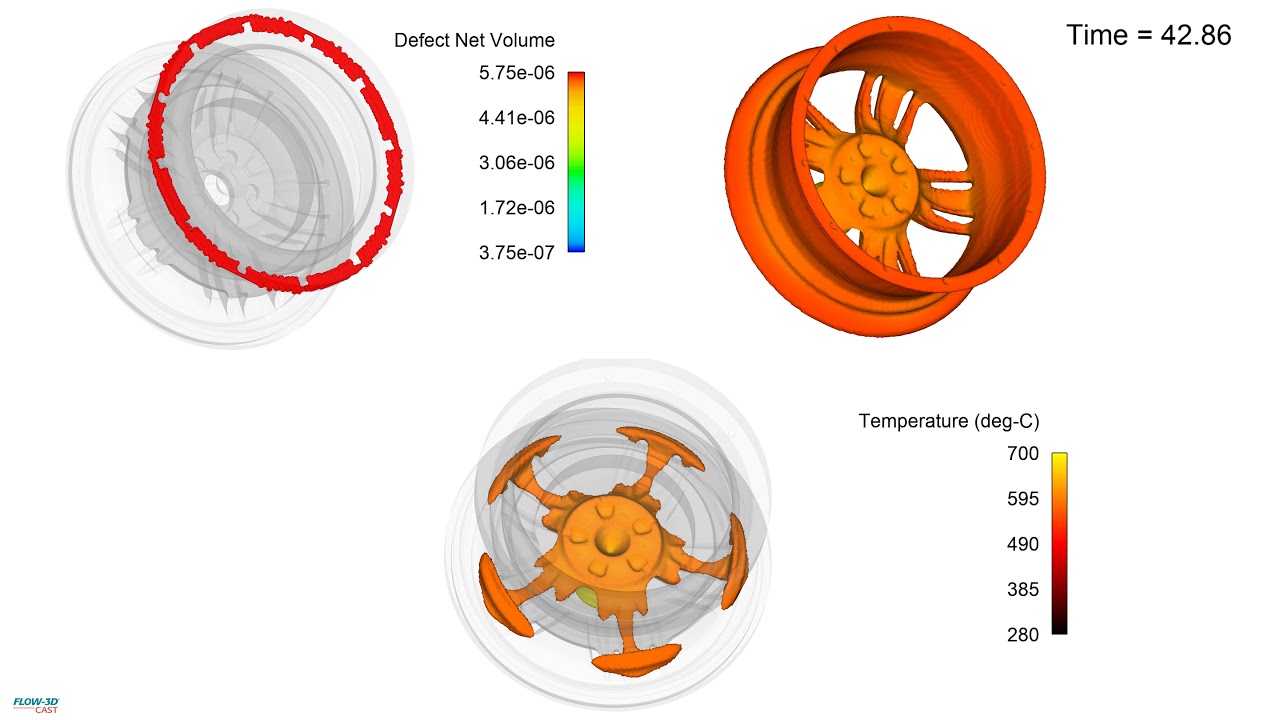

This FLOW-3D CAST simulation of an aluminum wheel low pressure die casting visualizes the solidification front and predicted net defect volume based on porosity. This example is part of a webinar on FLOW-3D CAST’s Low Pressure Die Casting Workspace.

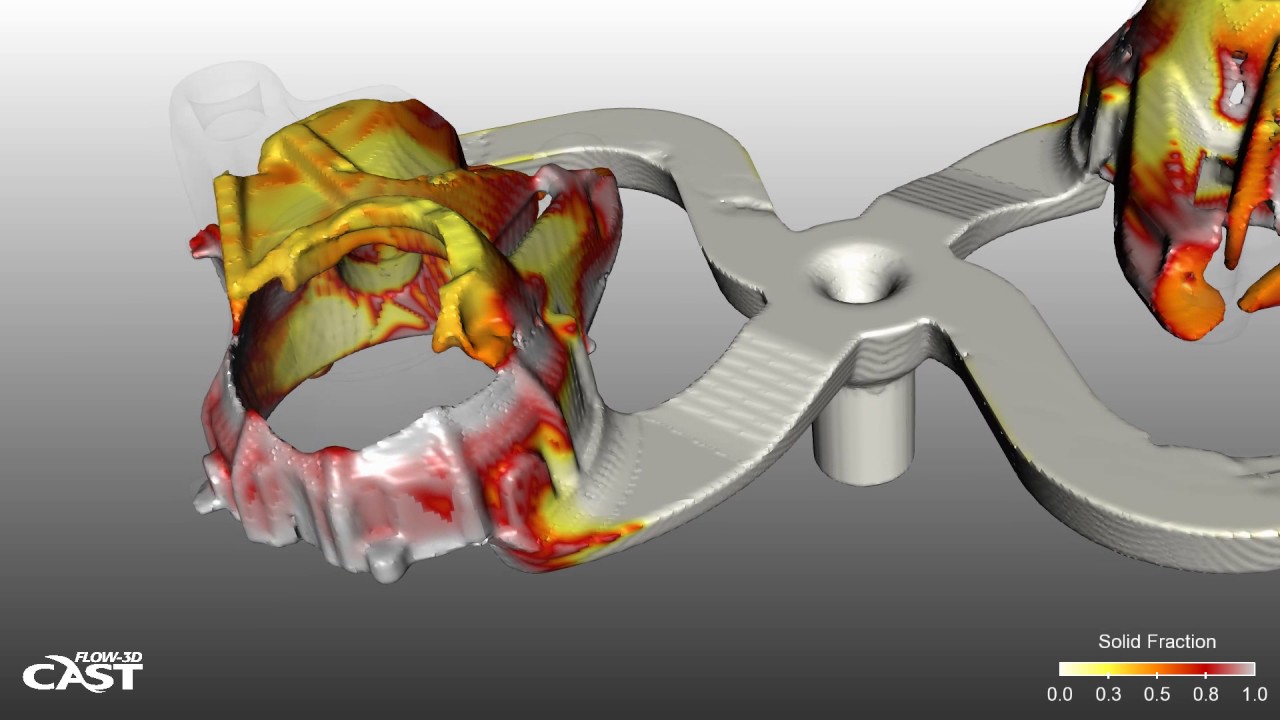

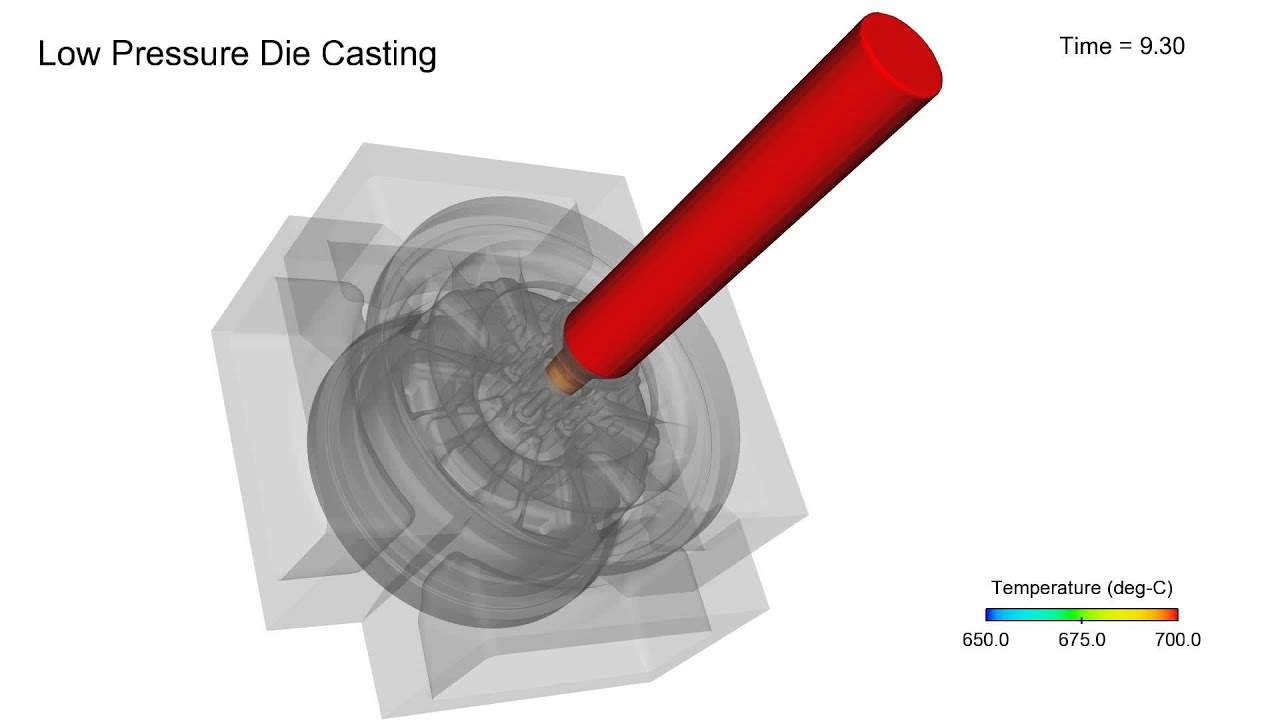

This FLOW-3D CAST simulation shows the filling analysis done to identify an area where a cold shut is produced. Simulation courtesy of XC Engineering. This example is part of an on-demand webinar on FLOW-3D CAST’s Low Pressure Die Casting Workspace.

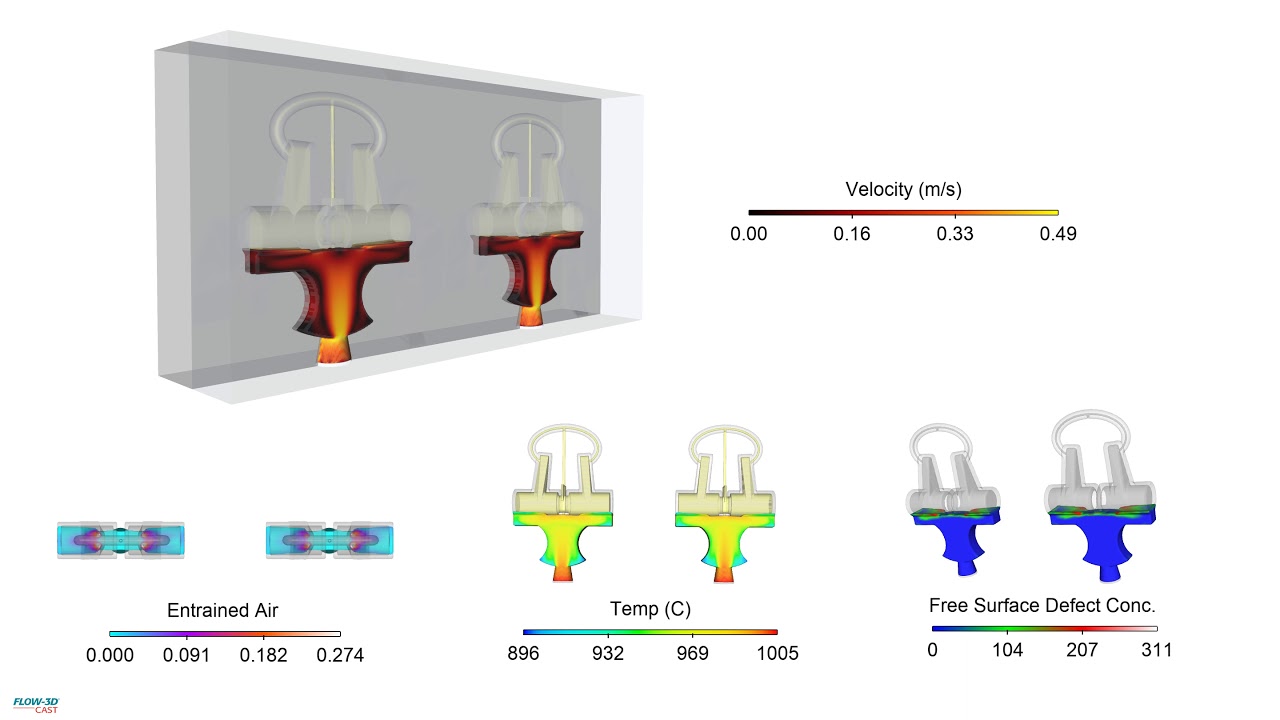

This FLOW-3D CAST filling simulation of a low pressure die casting of a brass faucet is used to analyze defects in the metal front. This example is part of a webinar on FLOW-3D CAST’s Low Pressure Die Casting Workspace.

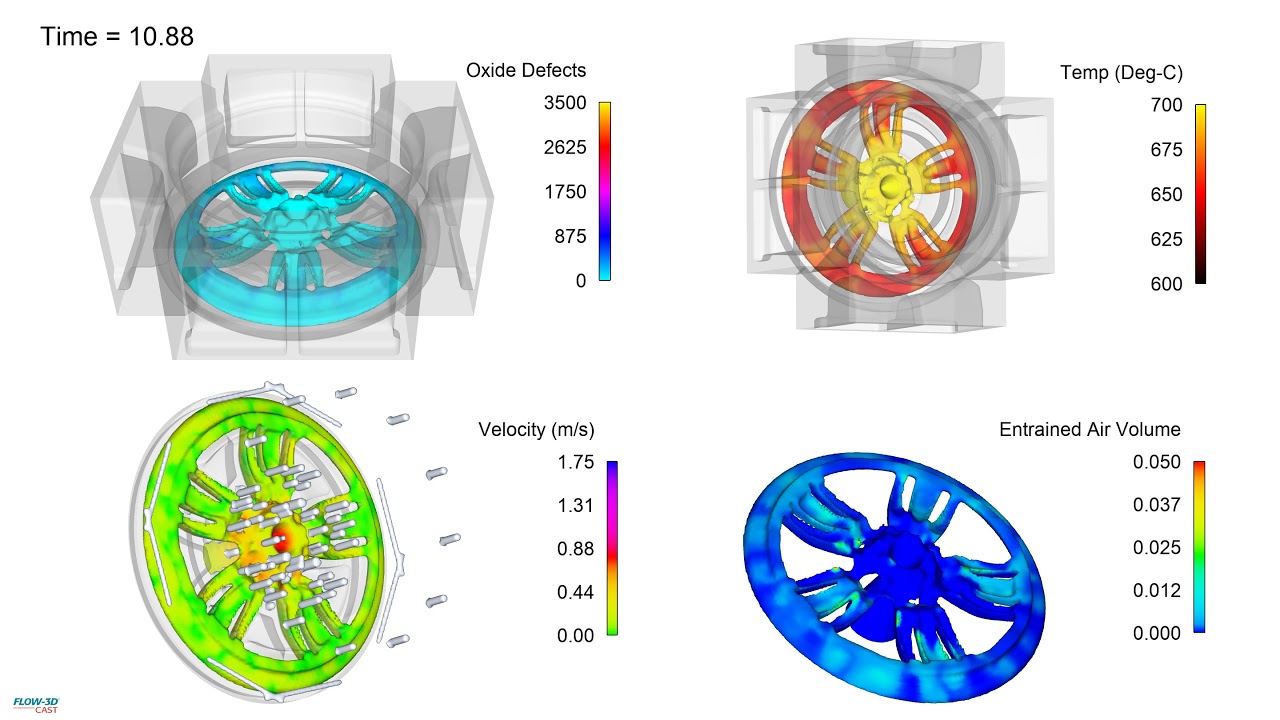

This FLOW-3D CAST low pressure die casting of an aluminum wheel simulation shows the filling analysis done to identify defects and propagation of the metal front.

Simulation of a low pressure die casting showing the filling temperature of a tire rim using FLOW-3D CAST.

Thermal die cycling is used to heat the mold components to proper operating temperatures before starting production. Proper analysis of die thermal management protocols can inform extended die life and part quality. Simulation can be used to assess areas of heat saturation over many cycles. Additionally, once a thermal steady state has been determined, the profile can then be used to inform a filling simulation with greater accuracy.

Processes modeled

- Gravity low pressure die casting

Flexible Meshing

- FAVOR™ simple mesh generation tool

- Multi-block meshing

- Nested meshing

Die thermal management

- Thermal die cycling

- Heat saturation

- Full heat transfer modeling

Advanced solidification

- Porosity prediction

- Shrinkage

- Hot spots identification

- Mechanical property prediction

- Microstructure prediction

Sand Cores

- Core gas evolution

- Material definitions for core properties

Vacuum and Venting

- Interactive probe placement

- Area and loss coefficient calculator

Ladle Motion

- 6 degrees of freedom motion definition

Filling Accuracy

- Gas and bubble entrapment

- Surface oxide calculation

- RNG and LES turbulence models

- Backpressure

Defect prediction

- Macro and micro porosity

- Gas porosity

- Early solidification

- Oxide formation

- Surface defect analysis

Dynamic simulation control

- Probe based triggers

- Heat Controls

- Vacuum and venting controls

Complete analysis package

- Animations with multi-viewports - 3D, 2D, history plots, volume rendering

- Porosity analysis tool

- Side-by-side simulation results comparison

- Sensors for measuring melt temperature, solid fraction

- Particle tracers

- Batch post-processing

- Report generation