High Pressure Die Casting Workspace Highlights

- Extraordinary fill accuracy

- Full process modeling includes advanced venting, PQ2, and spray cooling

- Dynamic simulation control allows dynamic runtime process control

- State-of-the-art aluminum silicon alloy solidification

The High Pressure Die Casting Workspace is an intuitive modeling environment designed to help engineers successfully model high pressure die casting applications with FLOW-3D CAST. Full control of shot sleeve motion, combined with advanced die thermal control, machine parameter modeling, and accurate resolution of fill and backpressure conditions make FLOW-3D CAST the reference solution for the most demanding HPDC simulation needs. In addition to advanced porosity prediction and post-processing functionalities, the HPDC Workspace includes a state-of-the-art chemistry-based solidification and material strength model for Al-Si and Al-Cu based alloys.

High Pressure Die Casting Playlist

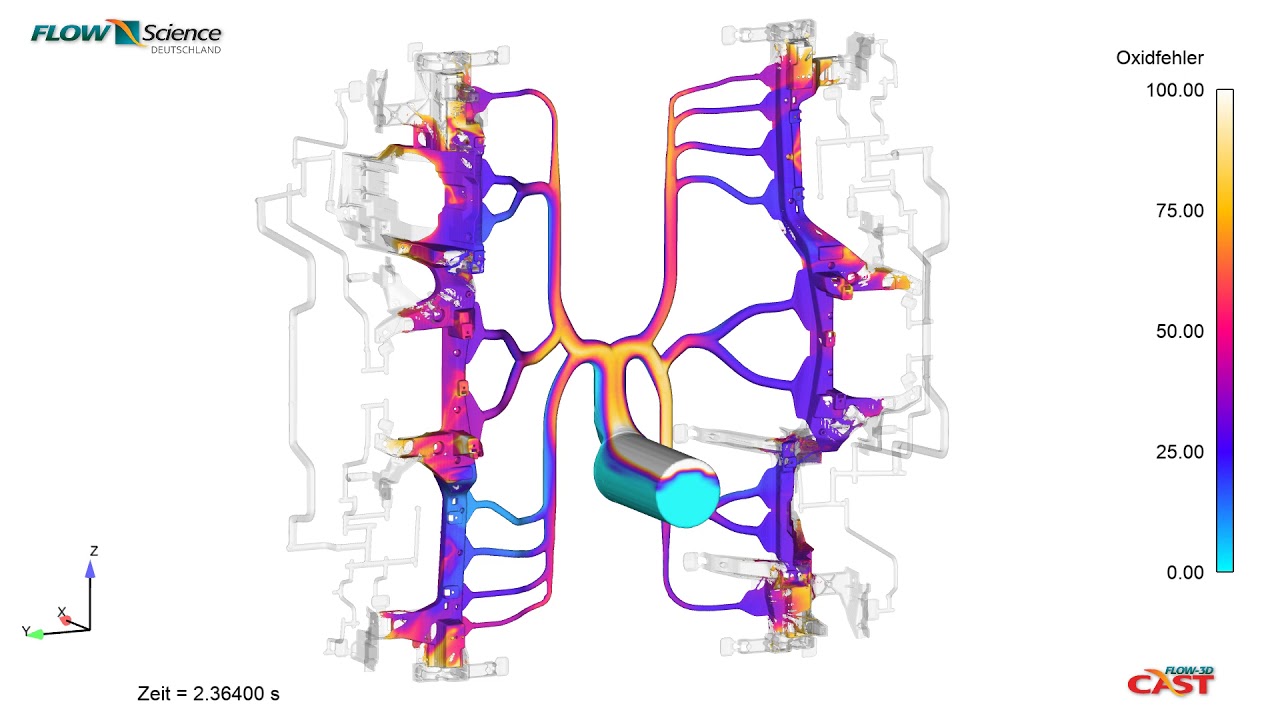

FLOW-3D CAST‘s defect tracking capabilities help casting engineers predict where surface oxide defects are most likely to occur from the filling process. Oxides form due to an exposed molten metal surface to air and can end up in the part in undesirable locations. The final location of the defects depends on the overall flow conditions, turbulent mixing, fluid jetting and impingement. FLOW-3D CAST accurately tracks these oxides and their final locations to help improve designs.

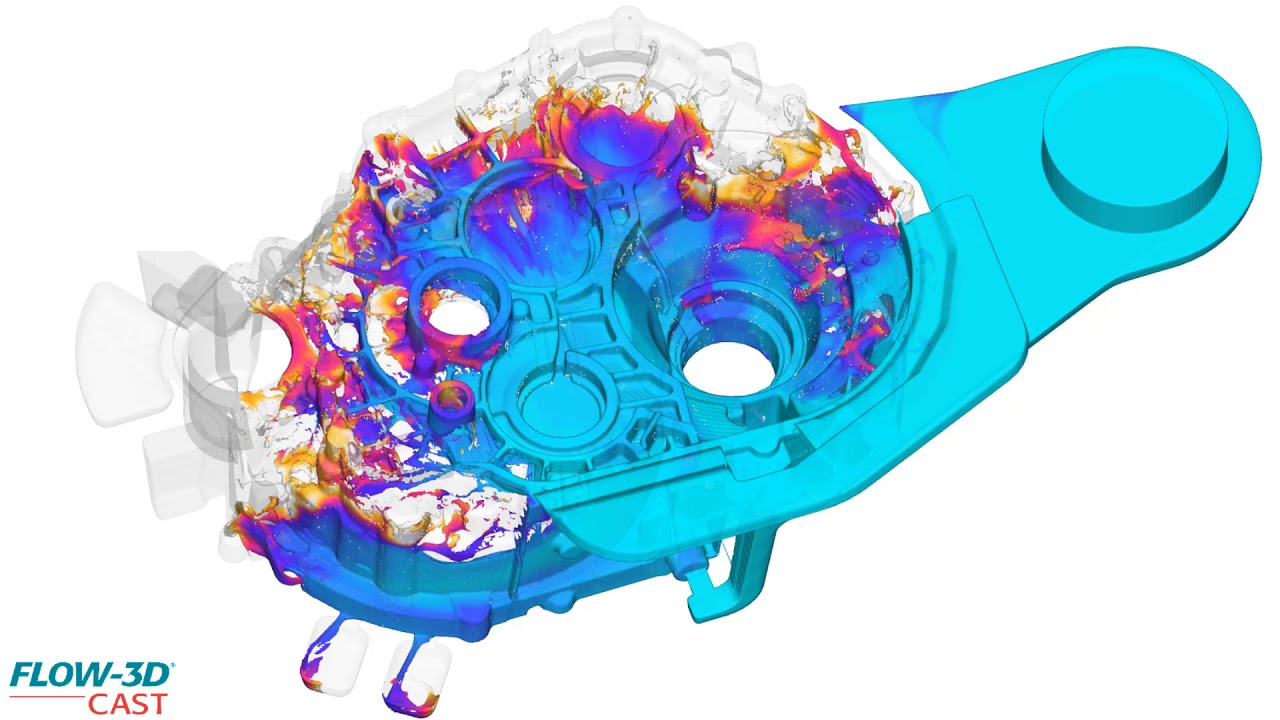

This FLOW-3D CAST filling simulation of a water pump shows the temperature distribution through a detailed filling pattern.

This FLOW-3D CAST filling simulation of an automotive component visualizes the oxide formation variable to understand where defects can become an issue in the filling process.

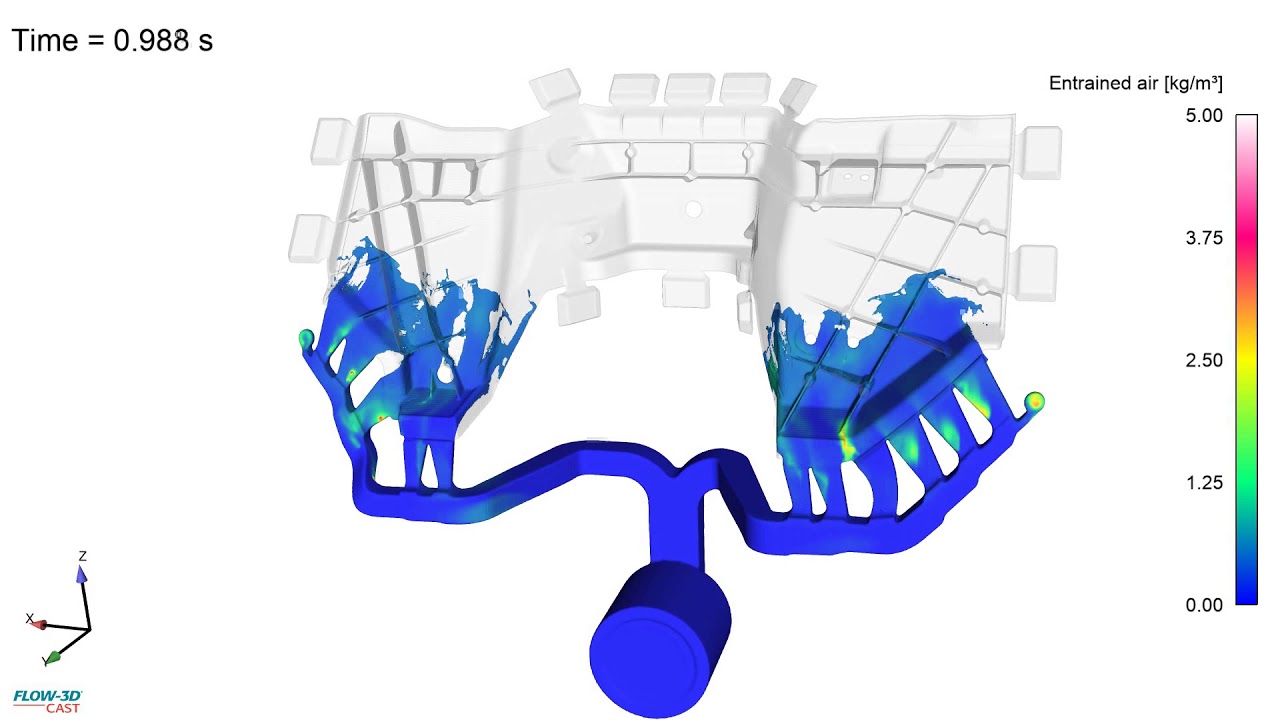

This FLOW-3D CAST filling simulation of a complex thin walled part shows the air entrainment variable to understand where defects can become an issue in the filling process. Visualization of air entrainment can be used to understand die venting, back-pressure, and areas of porosity.

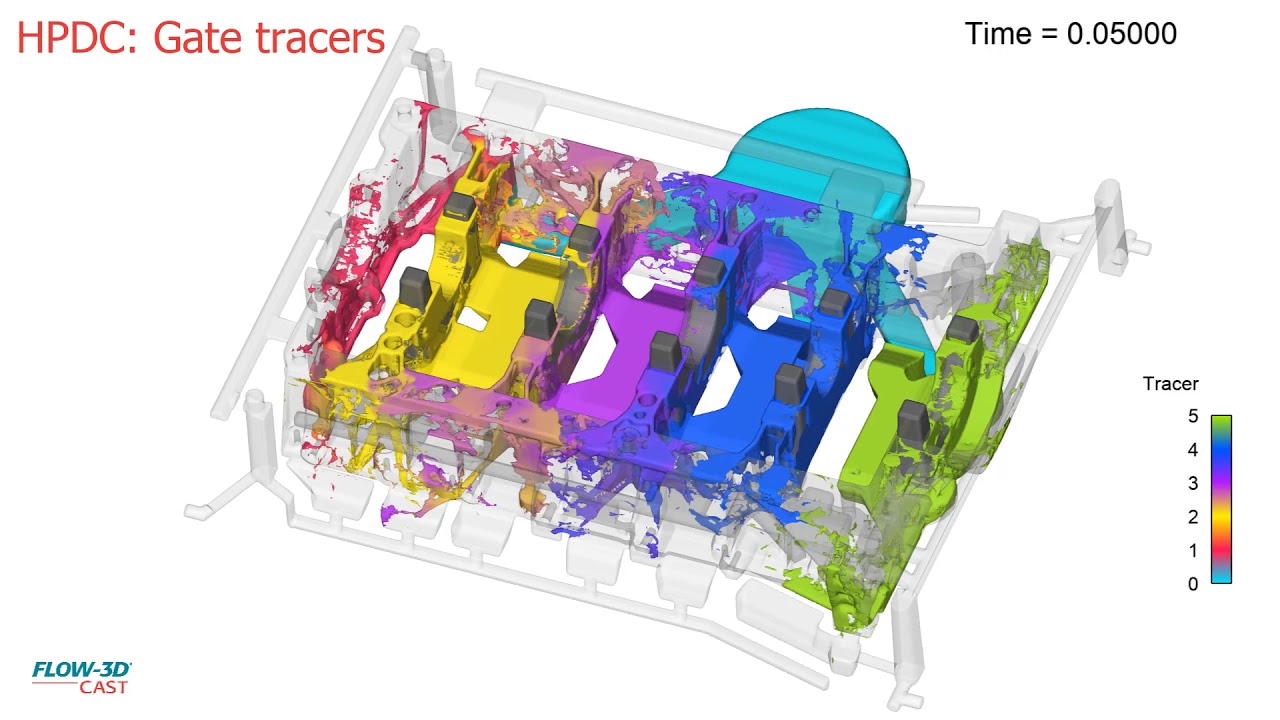

This FLOW-3D CAST filling simulation of a complex thin walled part with salt cores shows the use of gate tracers to visualize rigging performance.

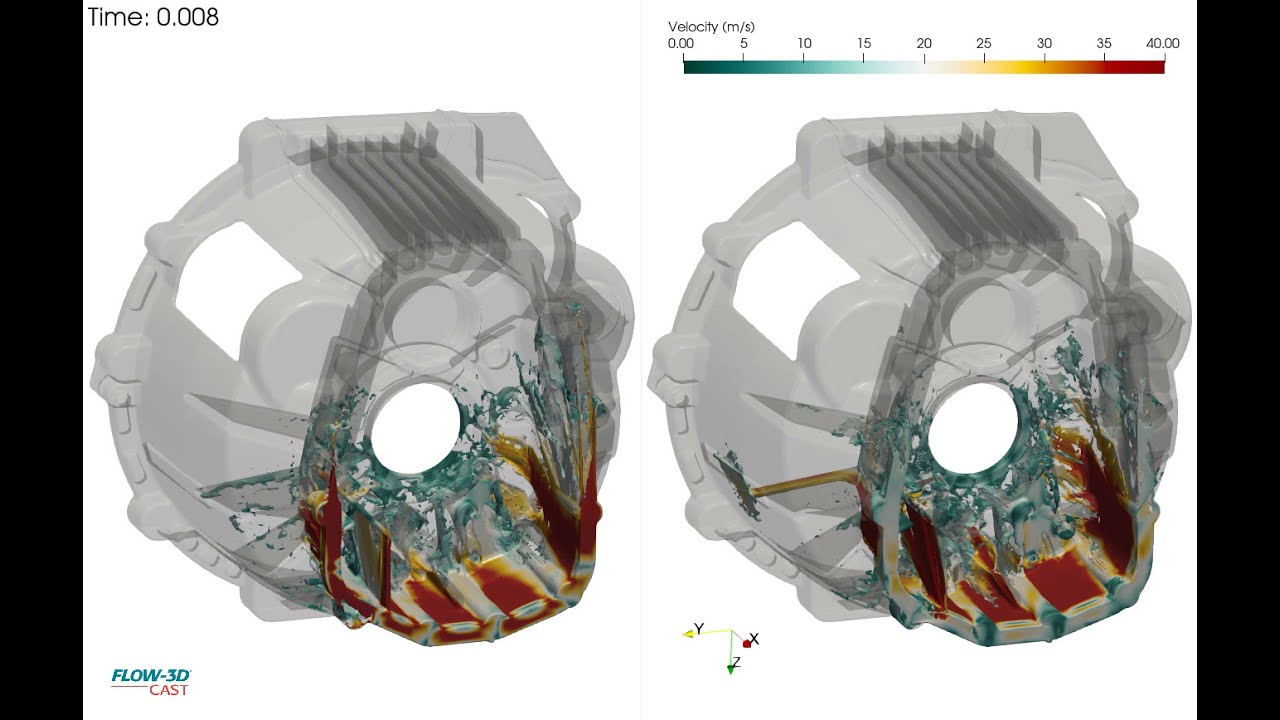

This is a simulation of an automotive flywheel or bell housing, showing velocity contours of an aluminum alloy during a fast shot of a high pressure die casting process. It is part of a design phase to evaluate different gating options. Shown here is a comparison of five gates, simulating filling from a runner below the parting line to accomplish an 80-millisecond casting fill. The left-hand simulation in the video shows gates pointed upward below the parting line, while the right-hand simulation shows gates at the same location, angled at 45 degrees. Learn more at www.flow3d.com/cast.

Processes modeled

- High pressure die casting

Flexible Meshing

- FAVOR™ simple mesh generation tool

- Multi-block meshing

- Nested meshing

Die thermal management

- Thermal die cycling

- Heat saturation

- Full heat transfer modeling

- Smart cooling channel control

- Spray cooling path modeling

Advanced solidification

- Porosity prediction

- Shrinkage

- Hot spots identification

- Mechanical property prediction

- Microstructure prediction

Ladle Motion

- 6 degrees of freedom motion definition

Vacuum and Venting

- Interactive probe placement

- Area and loss coefficient calculator

Filling Accuracy

- Slow and fast shot modeling

- Intensification pressure effects

- Gas and bubble entrapment

- Surface oxide calculation

- RNG and LES turbulence models

- Back pressure

Defect prediction

- Macro and micro porosity

- Gas porosity

- Early solidification

- Oxide formation

- Surface defect analysis

Surface Defect Analysis

- PQ2 analysis

- Probe based triggers

- Heat controls

- Vacuum and venting controls

Complete analysis package

- Animations with multi-viewports - 3D, 2D, history plots, volume rendering

- Porosity analysis tool

- Side-by-side simulation results comparison

- Sensors for measuring melt temperature, solid fraction

- Particle tracers

- Batch post-processing

- Report generation