Centrifugal Casting Workspace Highlights

- Advanced motion controls allow for precise simulation of all spin permutations

- Solutions include horizontal pipe casting, vertical jewelry casting, vertical large-scale spin

- Dynamic spin rate control during solidification

Workspace Overview

The Centrifugal Casting Workspace provides centrifugal casting users with an easy-to-use tool for simulating horizontal and vertical true centrifugal castings, semi-centrifugal castings, and centrifuge castings. With the new Centrifugal Casting Workspace, users will find all the tools needed to model their process and optimize design parameters. Pinning molds and rotating meshes provide users with the flexibility to model any mold motion imaginable including ladle pouring.

Cylindrical meshing delivers the greatest flow modeling accuracy possible, while multi-block meshing provides an efficient method for even more accuracy in high shear and high temperature gradient regions of the casting. The solution predicts flow-related issues such as raining due to inadequate mold rotation speed, and defects such as air entrainment or remelting of solidified regions. Process parameters such as mold preheat temperature, cooling configurations, and mold rotation rates can all be part of the model setup.

Centrifugal Casting Playlist

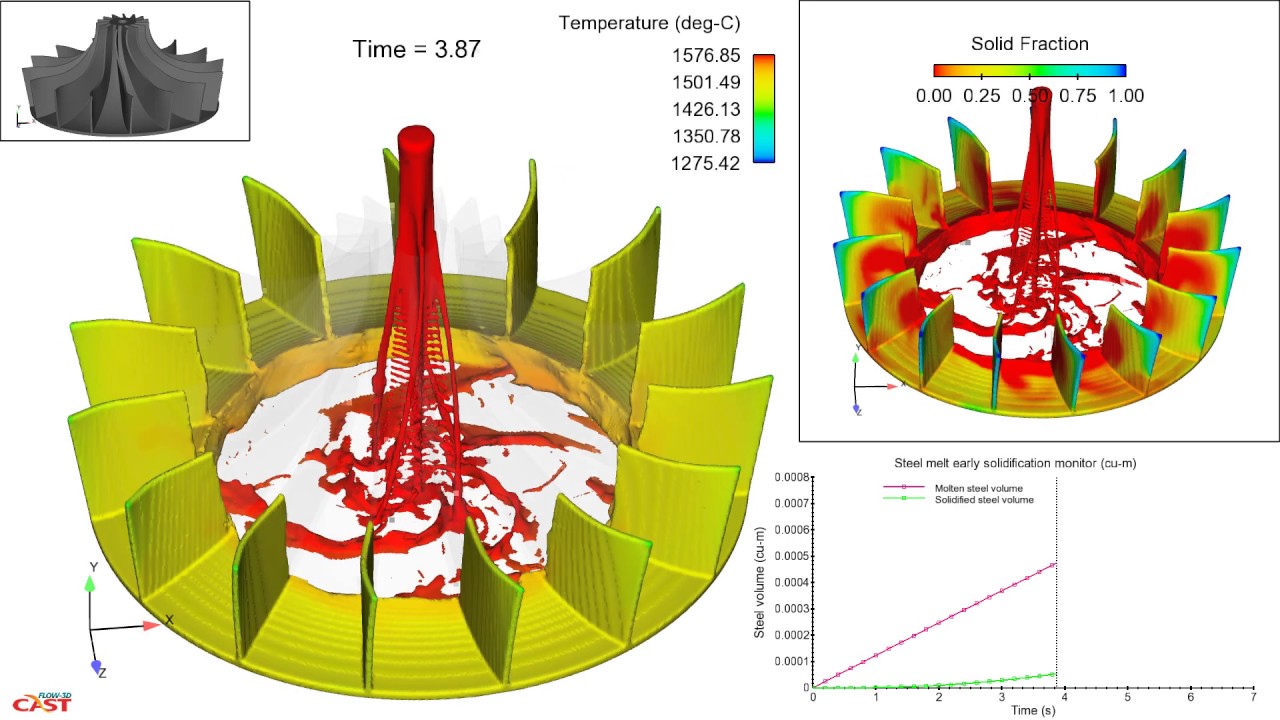

Partial filling simulation of a steel impeller centrifugal casting process. The spin is set at 250 rpm. FLOW-3D CAST simulation software is used to simulate and show early freezing issue in casting impeller vanes. Courtesy of Simulated Engineering Incorporated.

This simulation represents the vertical centrifugal casting of an aluminum A356 flange. Melt is introduced into the mold via a vertical sprue at a rate of 5 kg/s. The mold is spun about its vertical axis at 500 rpm, providing an outward acceleration of 200 g at the surface of the mold. The left frame shows the pickup of the melt by the mold and helps determine the rate at which the melt distributes vertically over time. The upper right frame shows the solid fraction in the melt; this analysis helps determine the proper mold preheat to avoid premature solidification. In the lower right frame, the entrained air mass concentration is shown. As long as solidification does not occur prior to complete filling, all of the entrained air will be forced to the inner diameter of the casting, to be machined off later.

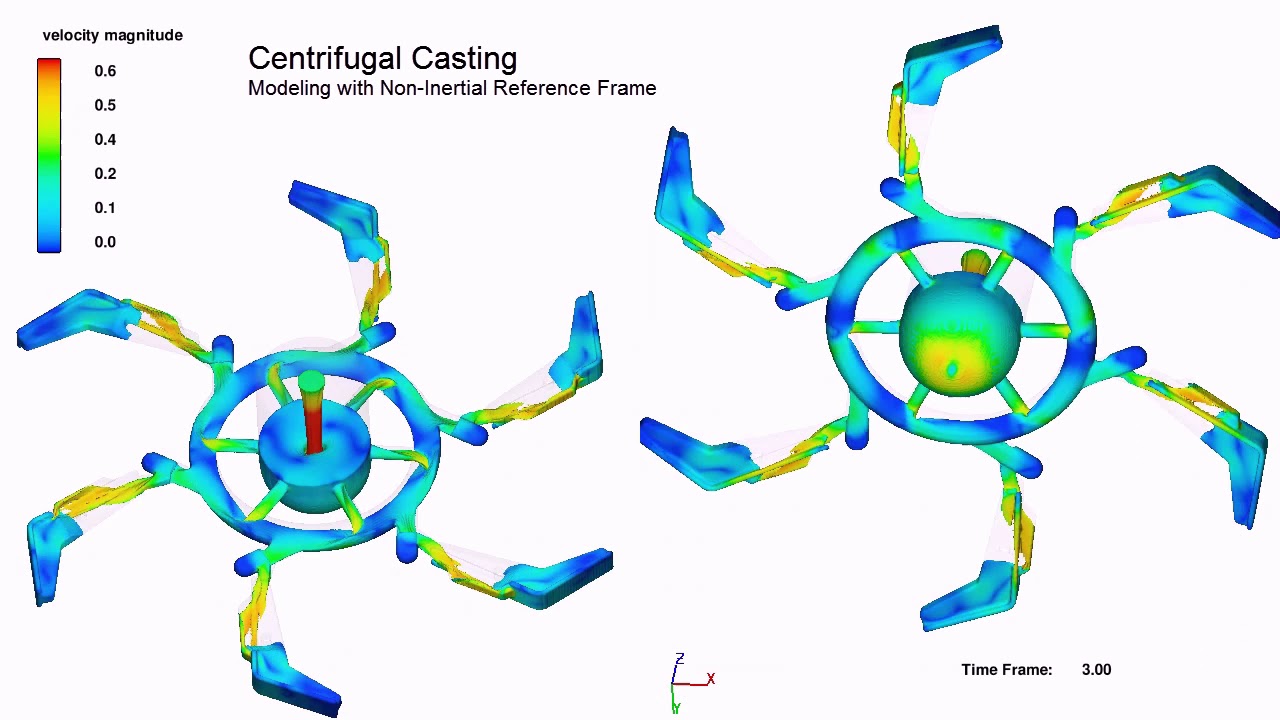

This centrifugal casting filling simulation with non-intertial reference frames allows the user to view the fluid front in the rotating mold. Simulation courtesy of Simulated Engineering.

Processes modeled

- Horizontal and Vertical true centrifugal processes

- Semi-centrifugal processes

- Centrifuge

Thermal mold modeling

- Localized die heating controls with heating elements

- Convective and radiative heat transfer

Flexible Meshing

- Cylindrical meshes for best accuracy

- Multi-block meshing captures flow and temperature gradients

Filling accuracy

- Melt pickup and rainfall prediction

- Gas/bubble entrapment

- Surface oxide calculation

- RNG and LES turbulence models

Mold motion control

- Vertical and horizontal rotation

- Variable spin rates

Ladle Pouring

Advanced solidification

- Shrinkage

- Directional solidification

Defect prediction

- Porosity prediction

- Entrained air

- Early solidification

- Oxide formation

Dynamic simulation control

- Pour control based on flow dynamics

Complete analysis package

- Animations with multi-viewports - 3D, 2D, history plots, volume rendering

- Porosity analysis tool

- Side-by-side simulation results comparison

- Sensors for measuring melt temperature, solid fraction

- Particle tracers

- Batch post-processing

- Report generation