Unlike continuous microfluidics, droplet based microfluidics manipulates only discrete volumes of fluids. Microscale droplet systems can also allow for high throughput if there is a deep understanding of the droplet dynamics. Computational fluid dynamics is a very useful tool for understanding and predicting the behavior of such systems. The study of droplet dynamics through numerical simulations has been instrumental in the proliferation of inkjet technology. Over the last decade, FLOW-3D has been established as the preferred analysis tool for such studies, for both commercial and academic applications. FLOW-3D has been used to study acoustically induced inkjets, piezo inkjets, thermal bubble inkjets and many other types.

Equipped with a powerful surface tension model and a successful history of inkjet modeling, FLOW-3Dnaturally extends to modelling droplet based microfluidics processes. FLOW-3D is nowadays used to simulate precision droplet creation, precision droplet deposition, droplet merging, droplet breakup, droplet motion, flow focusing, inkjet printing and droplet T-junctions among other applications.

Precision Droplet Creation

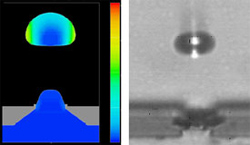

The rapid, repeated, precise creation and deposition of droplets, printing or patterning of small features (say l = 10-3-1 mm), and the formation of thin films with controlled, uniform thickness by spraying, are of great importance to a variety of old and new industrial applications (1-5). The liquid transfer and drop formation/deposition processes involve complex free-surface flows and formation of columnar necks that undergo spontaneous capillary-driven instability, thinning and pinch-off (1-5). Despite the progress made using experimental, theoretical and one-dimensional simulation studies for analyzing drop formation and liquid transfer for simple Newtonian and inelastic fluids, mechanistic understanding of printing and spraying remains a challenge. The primary motivation for the present computation effort is to examine the possibility of using the volume-of-fluid (VOF) approach embedded in the FLOW-3D to obtain mechanistic understanding of pinch-off dynamics of Newtonian fluids. We show that our computational analysis captures the complex interplay of capillary, inertial and viscous stresses that determines the self-similar capillary thinning and pinch-off dynamics. For the drop formation and detachment of Newtonian fluids, we show that the self-similar neck evolution obtained from the computational analysis can be described using the universal scaling laws expected from theory and 1D simulations (1-7) as well as experiments (1, 2, 8-12). Our success in simulating such prototypical flows is a necessary step towards using FLOW-3D for careful computational analysis of the nonlinear dynamics underlying finite-time singularity, satellite drop formation as well as printability in more complex geometries, that are significantly harder to describe or study using 1D models and experiments.

Courtesy of University of Illinois at Chicago.

Read the Computational Analysis of Drop Formation and Detachment case study.

Inkjets

Despite the continuing move towards a “paperless” world, the market still hungers for simple, low-cost inkjet printers with more and more demand for high quality. The rapid proliferation in the use of digital cameras means more consumers also require high-quality color photo printing capability in their homes. This drives printer manufacturers to design better ways to satisfy the consumer demand through exotic design alternatives. Inkjet manufacturers around the world use FLOW-3D to improve the performance of their printers. Design engineers can study droplet generation (volume, shape, velocity, satellite creation), and the effect of nozzle geometry, temperature, bubble energy and surface tension on these variables.

Acoustically-induced Inkjets

There are numerous ways to force ink out of the nozzle of a printhead. Examples include mechanical pistons, vibrating diaphragms and the generation of vapor bubbles. In all cases, however, the goal is not just to force ink out of the nozzle, but also to limit the amount of ink so that it will deform into a droplet of a specified amount and moving at the desired velocity towards the surface to be printed.

These requirements impose strict limitations on the driving pulses. An alternative method to help in the pinch off of ejected ink is to change the surface tension of the ink in a non-uniform way. In the example shown here, FLOW-3D was used to simulate what happens when the ink’s surface tension is changed by localized heating at the exit of a nozzle. The images to the left show the simulated droplet and an experimentally observed droplet.

This acoustically-induced inkjet animation shows a pressure-induced jet, which is unable to break off due to high surface tension forces and the same situation with heat added. The modified surface tension in the heated jet breaks off a droplet.

Continuous Inkjets

Continuous inkjets, consisting of a stream of ink broken into regularly spaced droplets, are often used in industrial applications to write batch numbers and expiration dates on manufactured items. A continuous jet of liquid is subject to instability as first described by Lord Rayleigh, who showed that axisymmetric jets of liquid are unstable to disturbances whose wave-length exceeds the circumference of the jet.

To add some measure of control and reproducibility to continuous inkjets, a prescribed perturbation is typically applied at the jet origin that insures a breakup of the jet into a series of regularly spaced droplets. The accompanying figure shows a FLOW-3D simulation of a continuous jet having an initial diameter of 60μm and a mean axial speed of 10m/s. The jet liquid has the properties of water. A sinusoidal perturbation of frequency 12.57e4rad/s in velocity at the jet origin results in the breakdown of the jet into droplets.

Read the Continuous Inkjet Printing blog.

Piston-driven Inkjets

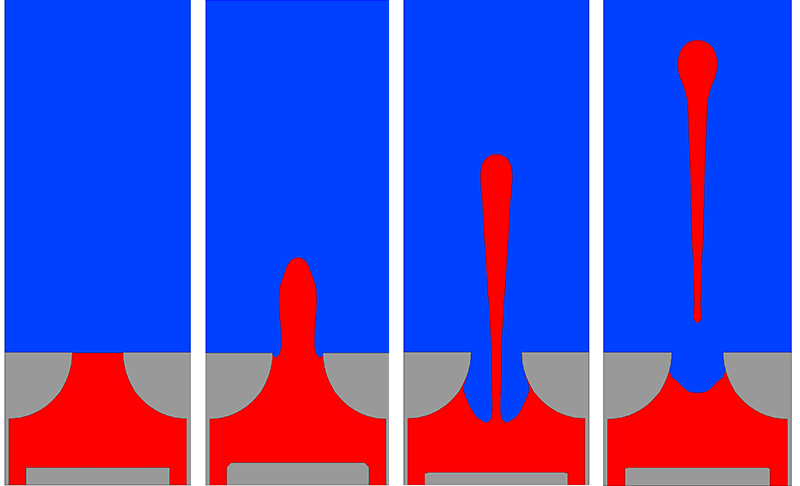

One reason why inkjet printers have become so inexpensive and their quality of printing so good is due to the research and development activities of competing manufacturers. The size of inkjets is typically in the range of 10 to 60 microns (a human hair is about 100 microns for comparison) and is so small that making experimental observations and measurements is difficult. For this reason, most research has included extensive computational modeling of print heads to provide guidance in how and where design improvements can be made. Simulations allow a researcher to study how the shape of ejected droplets is affected by parameters such as the driving pressure pulse, the shape of the nozzle, surface tension coefficient, and much more.

The example above shows the formation of a droplet from a nozzle that is driven by a moving piston. In this case the speed and displacement of the piston must be carefully selected to produce the proper amount of ink ejected and pinched off, while at the same time leaving a minimum disturbance in the ink remaining in the nozzle so that it can be quickly replaced by more ink from a reservoir. Usually, the replacement is by the action of surface tension pulling the ink up to the exit of the nozzle where it will be ready for the next pulse of the piston.

Pressure-driven Inkjets

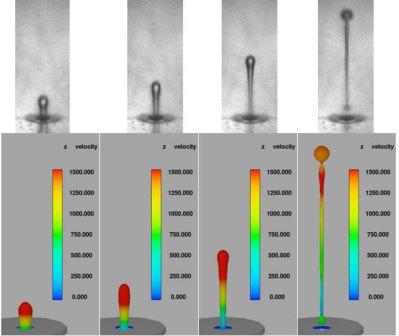

A popular means of generating inkjets for digital printing is to use a programmed pressure at the base of an inkjet nozzle device. Because of the almost unlimited combinations of driving pressure, shape of the nozzle, surface tension and viscosity of the ink and other variables, it is extremely useful to have a way to simulate ejected droplets under various combinations of these parameters. FLOW-3D can be used for this purpose because of its capabilities for modeling nearly all the physical processes that govern the formation of inkjets. Shown below is the formation of a droplet from a simple pressure-driven nozzle, where the upstream pressure history has been specified.

Thermal Bubble Jets

There are several ways in which inkjets are created to produce high quality digital printing. One effective technique is to create a vapor bubble of ink that expands pushing ink out a nozzle and then contracts and sucks ink back into the nozzle to pinch off the ejected ink. This fluid dynamic process involves a complex mixture of heat transfer, phase change, and pressure dynamics within both the fluid and vapor.

Bubble Modeling Options

- Adiabatic Vapor Bubbles—No heat exchange to surroundings

- Vapor Bubbles with Heat Transfer—Heat is transferred to/from fluid and solids

- Vapor Bubbles—Heat Transfer and Vaporization/Condensation

Alternative Drop Ejector Architecture from Eastman Kodak

The image on the left shows how a vapor bubble forms when an electric current is pulsed through a heater element in the base of the ejector. The heater’s temperature increases because of Joule heating and once the superheat temperature is reached in the fluid a vapor bubble is formed almost explosively because of the high vapor temperature. Bubble formation by evaporation of ink is governed by a kinetic theory phase-change model. Shortly after the bubble begins to expand and its vapor cools, condensation at the surface of the bubble causes it to collapse, which in turn causes the ink expelled from the nozzle to pinch off. Surface tension and viscous forces largely govern the dynamics of the ink jet and its conversion into discrete drops.

Multi-phase Flows

FLOW-3D, with its variety of physical models, can help researchers and developers optimize the performance of droplet-based microdevices. Droplet-based microfluidics can help enhance the performance of microchemical analysis systems, micromixing processes, chemical and biochemical screening, enzymatic kinetics, and assays. Fluid pressure, viscous and surface tension forces play a major role in the functioning of these microdevices. Go here for more information about the modeling multi-phase flows.

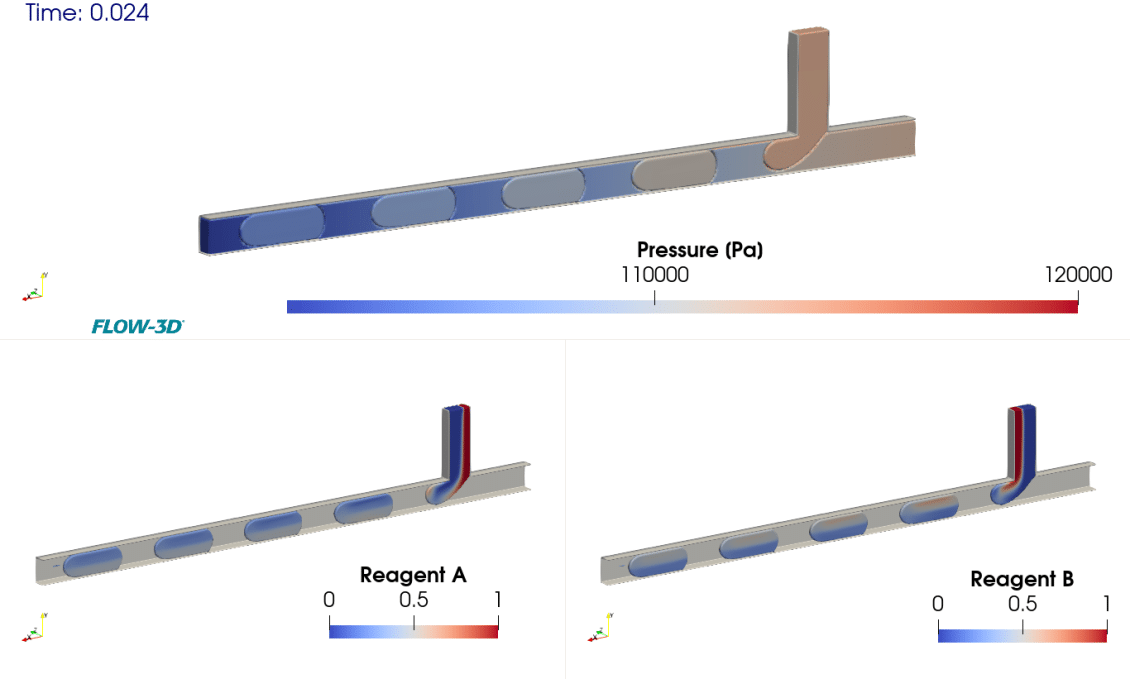

Two-Phase Microfluidic Channels

Droplet formation in two-phase microfluidic channel systems has been extensively studied for both immiscible liquid-liquid flows and gas-liquid flows. Droplet-based microsystems also enable miniaturization of reactions by confining reagents in droplets of femtoliter to microliter volumes. Confining reagents in droplets provides rapid mixing of reagents, control of the timing of reactions and the ability to synthesize and transport products.

Co-Flow

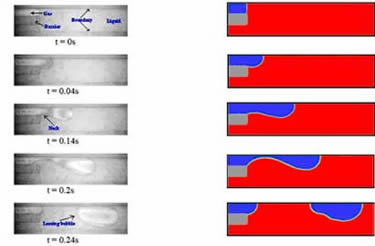

The FLOW-3D simulation below shows air bubble generation in a simple co-flowing micro channel. Water and air enter the microchannel from the same side (left), separated by a barrier. There are two steps in the bubble formation process. First the gas phase expands downwards and horizontally until a neck is formed, then the neck propagates downstream and its diameter decreases until it finally breaks.

In the simulation results above, blue denotes the gas (air) phase and red denotes the liquid (water) phase. Experimental results taken from Renqiang Xiong, Mo Bai, Yun Whan Na, Jacob N Chung, “Bubble generation in the micro-channel with a barrier,” Proceedings of FEDSM2007 5th Joint ASME/JSME Fluids Engineering Conference July 30-August 2, 2007 San Diego, California USA.