Investment Casting Workspace Highlights

- Full process modeling for investment casting processes

- Streamlined shell creation from casting pattern

- Advanced radiation model captures full radiative heat transfer between shell surfaces

- Advanced motion controls include Bridgman, ladle and spin dynamics

Workspace Overview

The Investment Casting Workspace provides investment casters with an easy-to-use tool for simulating all aspects of investment casting, including shell generation, filling, solidification (with either static or moving Bridgman shell molds), and cooling. A shell mold creation tool is provided for quick and reliable shell geometry creation, while radiation and view factor models accurately capture radiative heat transfer between different parts of the shell. For directional solidification, a moving oven with a hot upper section separated from a cooler lower section captures the Bridgman process. Melt surface evolution as well as mold motion, filling detail and solidification patterns are readily assessed through intuitive post-processing tools, allowing for process modifications to be implemented with confidence.Investment Casting Playlist

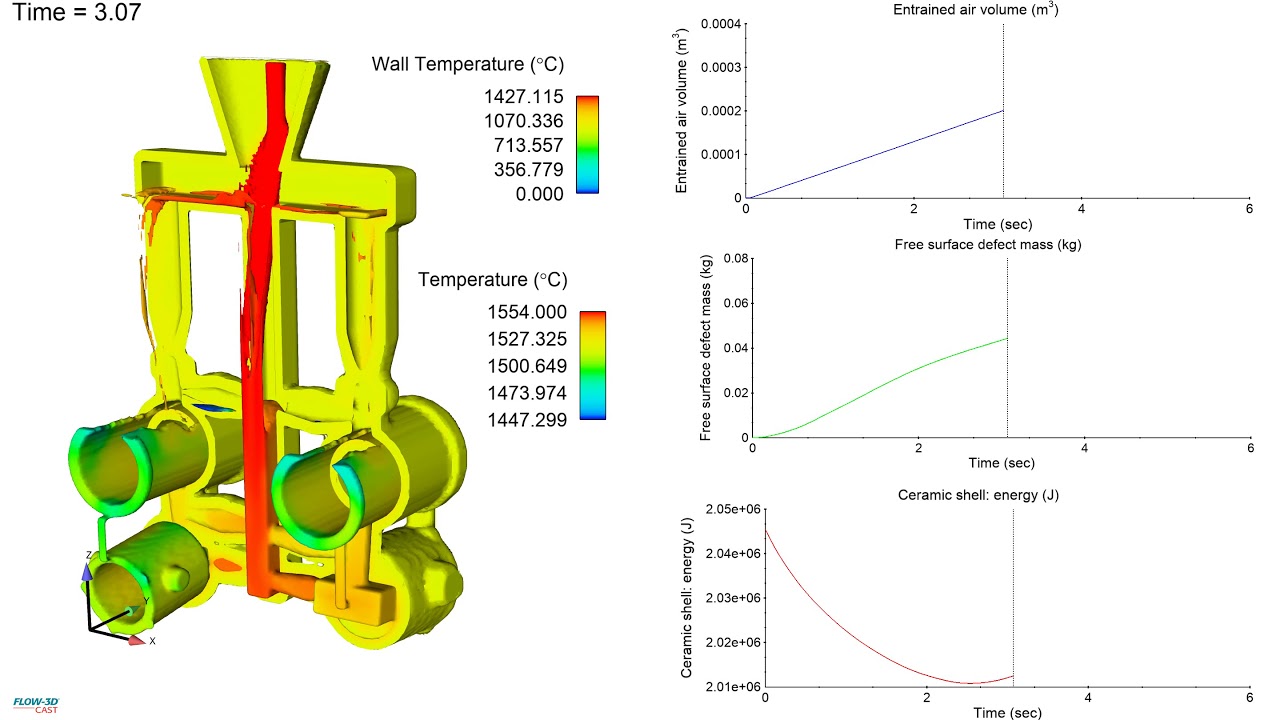

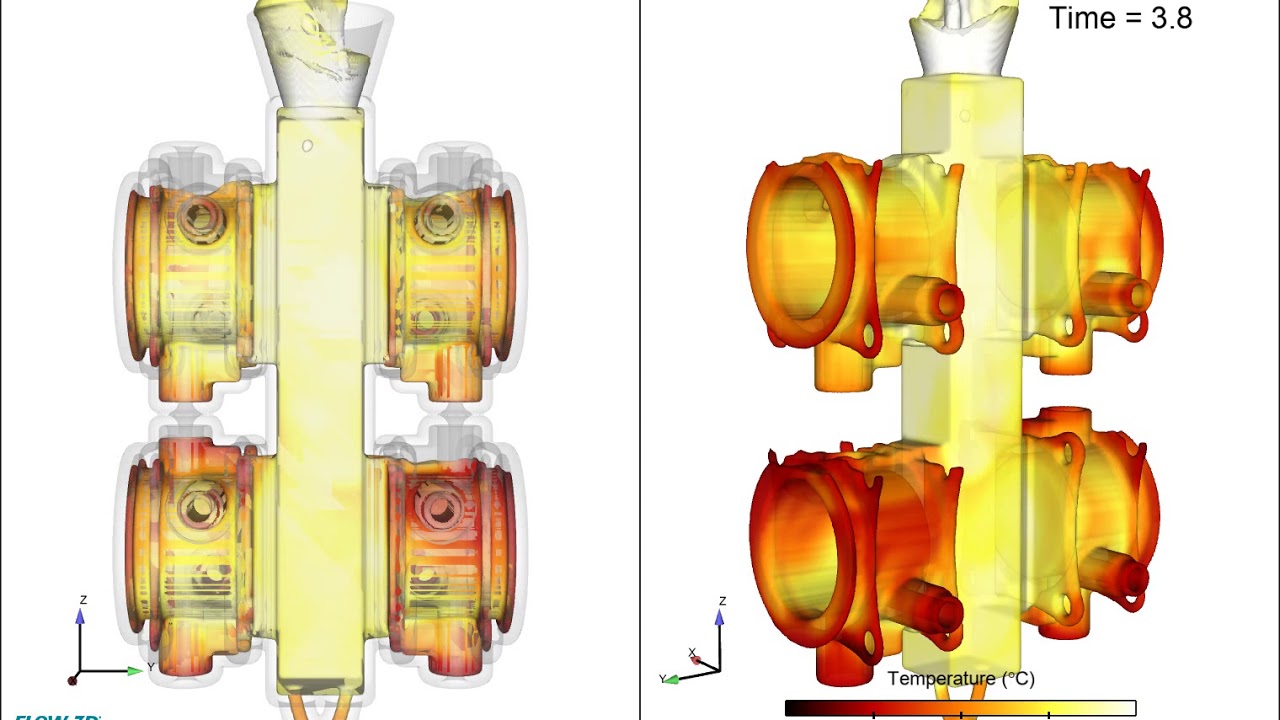

This FLOW-3D CAST filling simulation of an investment casting is used to assess the oxide formation, air entrainment, and heat transfer to the shell.

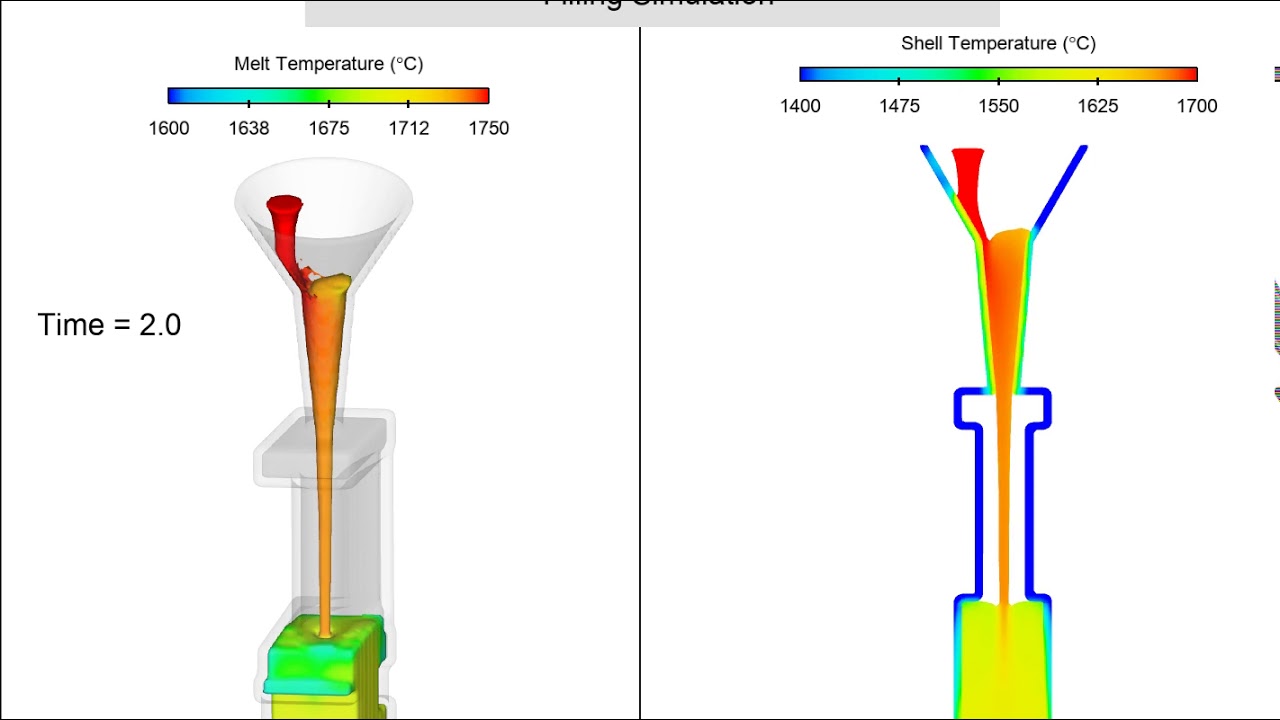

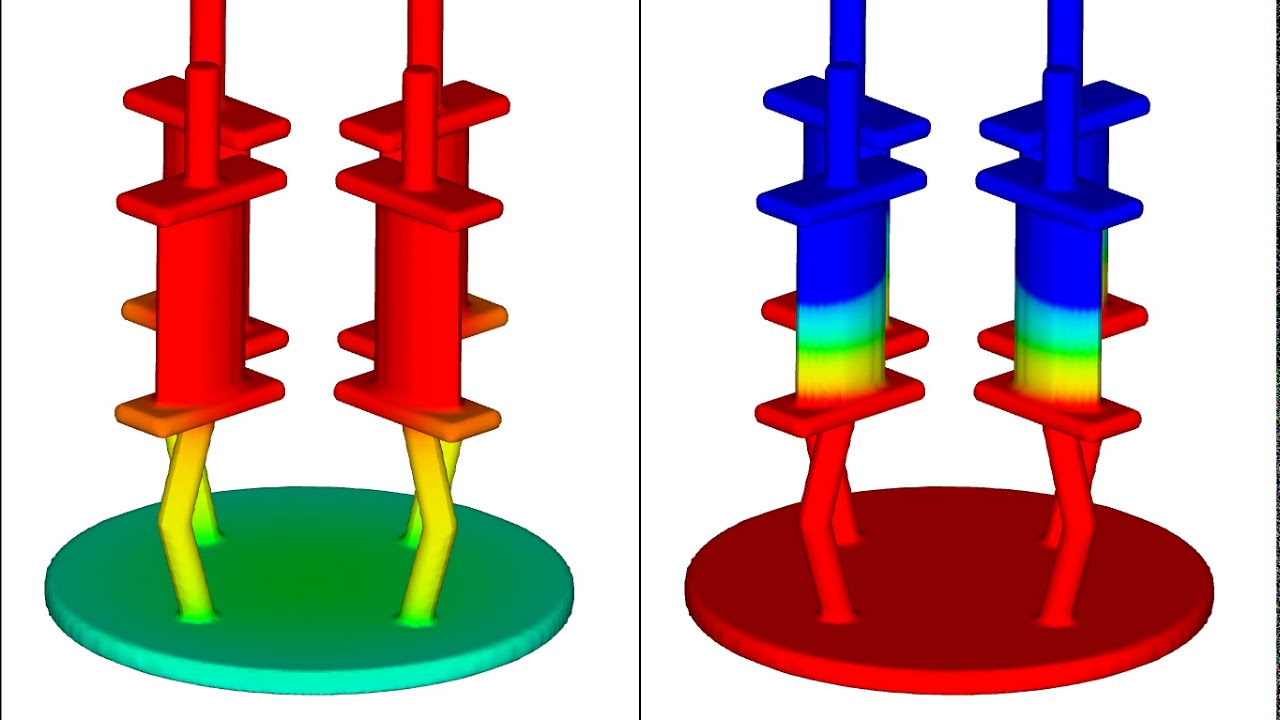

This FLOW-3D CAST simulation represents the investment casting of a turbine blade using a Bridgeman process.

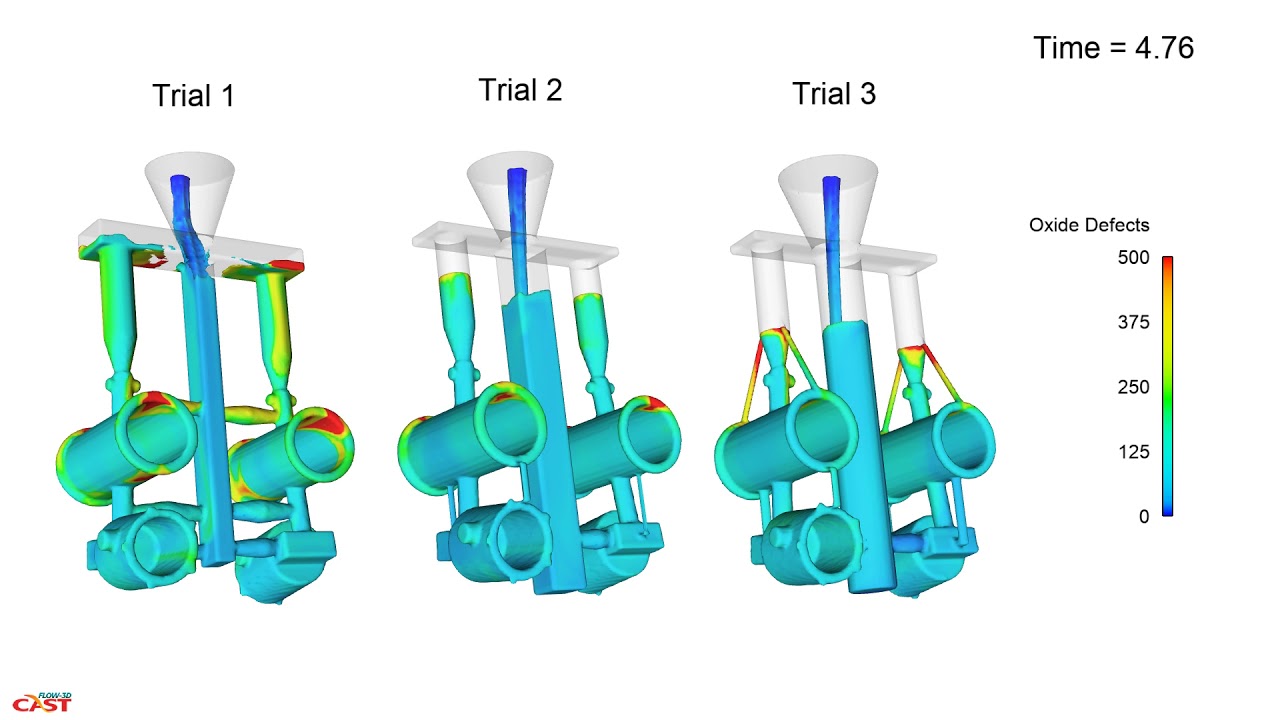

This investment casting simulation — comparing three design variations — predicts the oxide formation in the metal front. Design engineers can easily create multiple trials to explore variations for scrap reduction.

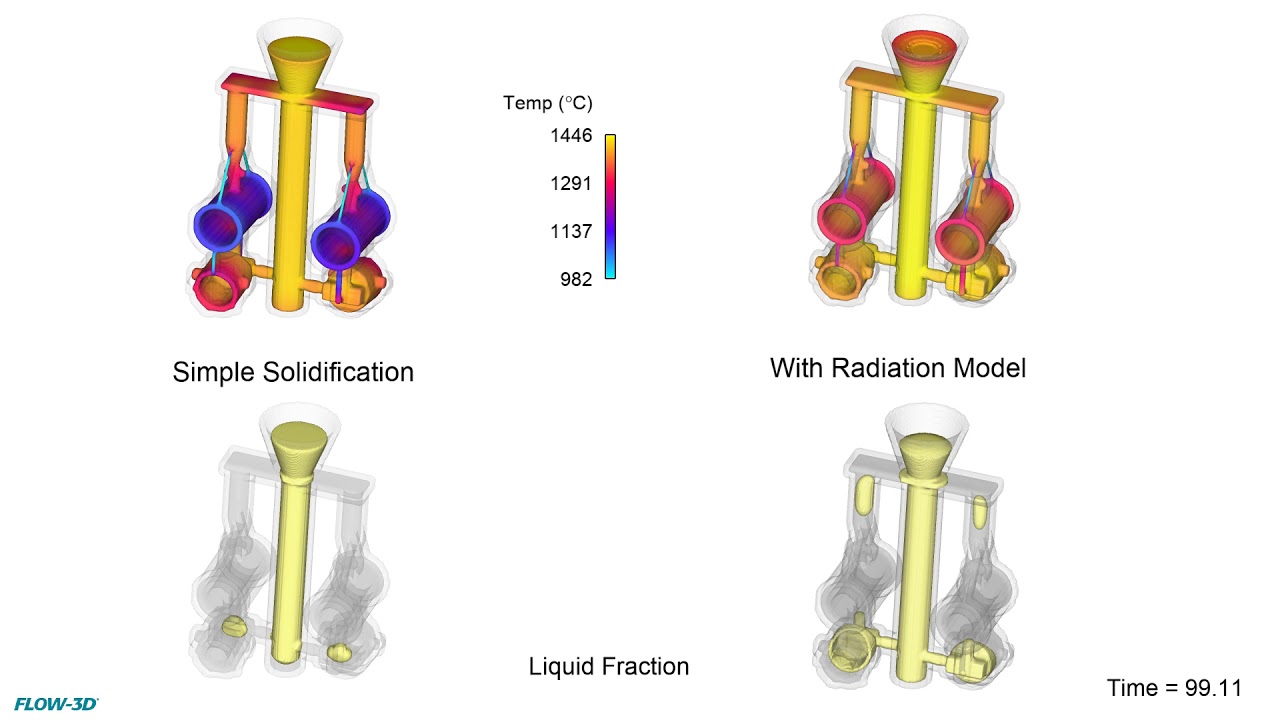

This investment casting simulation is used to compare the mold temperature distribution between radiating and non-radiating models. FLOW-3D CAST v5.1 contains a full body to body radiation model to accurately capture the solidification and cooling dynamics after fill.

The Investment Casting Process Workspace in FLOW-3D CAST v5.1 offers automatic shell generation in addition to advanced radiation modeling, in order to deliver extraordinary accuracy to aid the design modeling process.

The Investment Casting Process Workspace in FLOW-3D CAST v5.1 offers automatic shell generation in addition to advanced radiation modeling, in order to deliver extraordinary accuracy to aid the design modeling process.

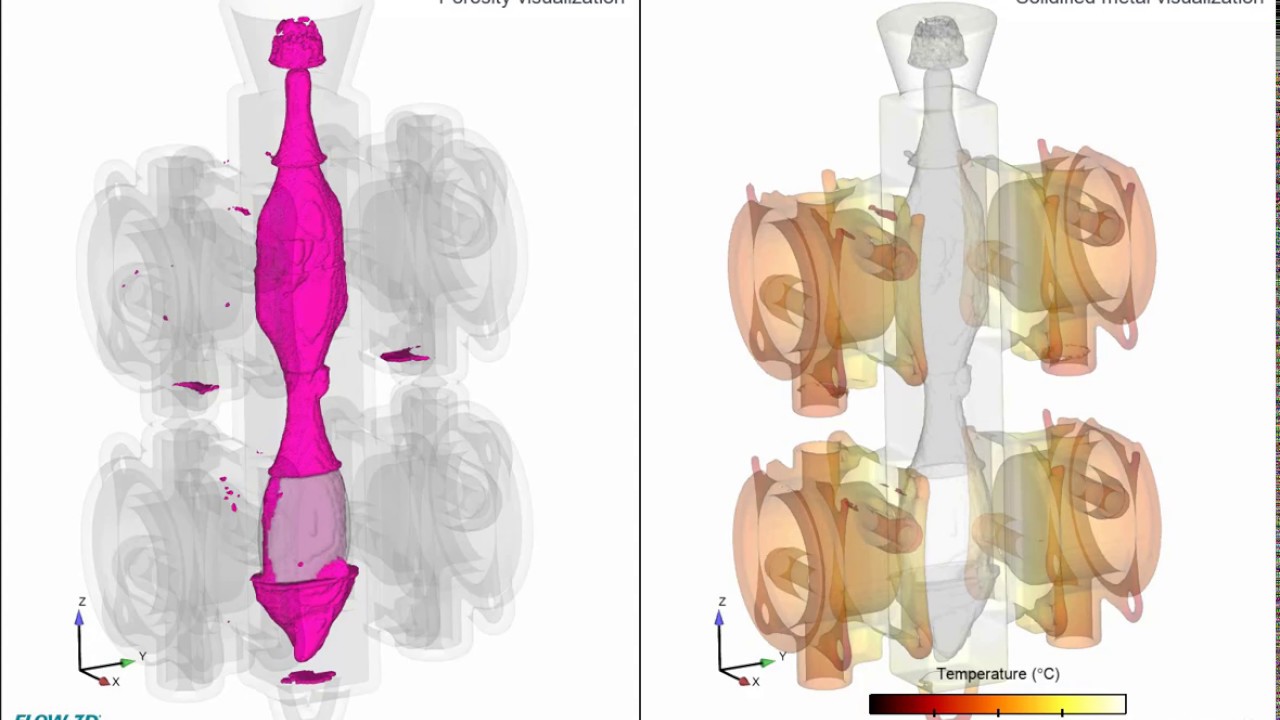

This simulation shows how the temperature distribution in the solidifying casting on the left and the solid fraction on the right. The feeders at the top of each part provide liquid metal to the casting as it solidifies and shrinks. Read our latest blog to delve into FLOW-3D CAST v5.1’s new Investment Casting Workspace at https://www.flow3d.com/simulating-the-investment-casting-process/

Processes modeled

- Filling

- Solidification – Static and Bridgman

- Cooling

Shell mold creation

Thermal mold modeling

- Full radiation modeling with view factors

- Convection and conduction heat transfer

Multi-block meshing

Extraordinary accuracy in filling simulations

- Gas/bubble entrapment

- Surface oxide calculation

- RNG and LES turbulence models

Ladle Pouring

Advanced solidification

- Porosity prediction

- Shrinkage

- Directional solidification

Defect prediction

- Porosity prediction

- Entrained air

- Early solidification

- Oxide formation

Dynamic simulation control

- Pour control based on flow dynamics

Complete analysis package

- Animations with multi-viewports - 3D, 2D, history plots, volume rendering

- Porosity analysis tool

- Side-by-side simulation results comparison

- Sensors for measuring melt temperature, solid fraction

- Particle tracers

- Batch post-processing

- Report generation